Vacuum Encapsulation of Aerospace Devices using Sanatron Equipment

Vacuum Encapsulation is a process of encasing items by utilizing a vacuum chamber. There are several reasons why encapsulation may be necessary, however they all boil down to protecting the original product thru sheathing or coating.

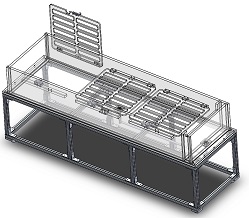

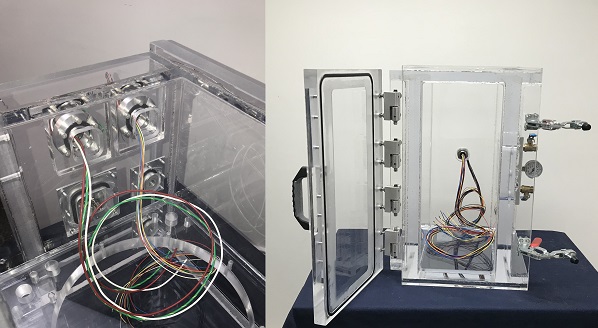

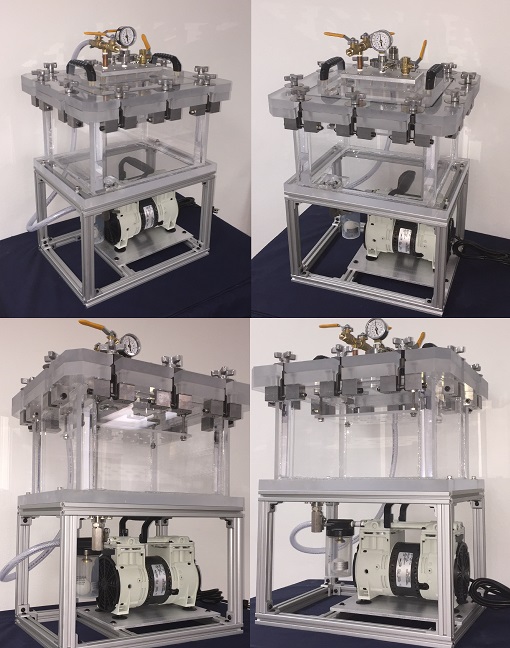

An aerospace customer of ours needed to build a vacuum encapsulation system for one of their product lines. This system included a vacuum chamber, a vacuum controller, a vacuum pump, a custom adjustable jig (placed inside the vacuum chamber), and several feedthroughs for wires and liquid gas feedthrough. The vacuum chamber was 18 inch Wide, 18 inch Deep, and 18 inch High with front loading hinged door. The vacuum pump which came with the system was a 11 CFM, Rotary Vane Vacuum Pump capable of reaching ultimate vacuum of up to 0.010 Torr or 10 milliTorr absolute pressure.

The vacuum encapsulation process works by placing the product onto the adjustable jig. Pulling the target vacuum of 0.475 Torr or 475 milliTorr. Holding it there for about 20 seconds. After 20 seconds have elapsed, the product is ready for vacuum potting. A nozzle will be rotated and placed directly above the product, the potting valve opens, and potting epoxy is dispensed onto the product fully covering it. Once the required amount of potting epoxy has been dispensed, the venting valve will open and the product will be brought to ambient pressures. Due to vacuum being present when the potting compound was dispensed, any gaps will be filled due to the fact that the vacuum is present inside the gap and ambient pressure present outside of the potting compound. If you are looking for a vacuum potting or encapsulation system, look no further, we have a wide variety of Vacuum Encapsulation systems which can be either manual or fully automated for a fully repeatable quality process. Contact us to find out how we can help you design, build, and deliver a quality built vacuum encapsulation system.

We have many more resources on our website that you should check out

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). Check out some of our other items we carry that you can combine/integrate with your systems or projects.

Complete List of Articles Related to Acrylic Vacuum Chambers