Vacuum Fabrication of Optical Equipment incorporating Custom Sanatron Systems

A large Optical Equipment Manufacturer contacted us to design, manufacture, and assemble a series of custom vacuum chambers to be incorporated into their assembly line. Their goal was to increase quality, capacity, and output. As you may know, optical equipment manufacturing is a high accuracy process requiring tremendous precision of manufactured parts during the fabrication process. The tolerances are in micrometers, even nanometers for some components. There is no room left for imperfection. If one component is slightly off, even if it’s just by a few micrometers or a few fractions of a degree, the performance of the optical equipment is dramatically decreased and the value provided to the customer will also follow that path.

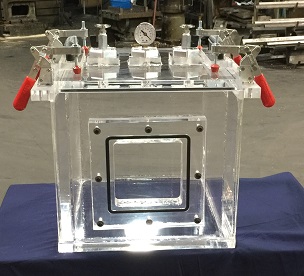

This is why our client was adamant in selecting and working with us. We are not just a machine shop “engineering things” as we go. How many times did you contact a machine shop to fabricate something simple only to be left with sub-par work? NOT WITH US! We are Scientist and Engineers who robustly design and quality manufacture vacuum systems. We understand how vacuum works on a much deeper level. And we are also very adamant when it comes to quality of manufacture and design. What you see here are three cylindrical custom vacuum chambers. The inside diameter is 12 inch at a height of 12 inch. There are three vacuum ports custom routed on the lid. The lid itself has a precision routed dovetail O-Ring groove which also includes a 0.25-inch cross section Viton O-Ring. The three custom ports will interface with the Optical Equipment manufacturing systems. These cylindrical chambers are capable of achieving 10 milliTorr of absolute pressure. This is unheard of for an acrylic vacuum chamber, because according to what others say: “polymers are not meant to be utilized at low vacuum applications”. Well, as you can see, that is not completely true, because we can do it. When acrylic is used for low vacuum applications, a certain dedication to quality and precision must be present in the persons heart during the fabrication process in order to make such chamber. This is something not many have and the reason we are able to help our clients when they need us.

We certainly did not mean to brag. At the time of writing this, we have been making vacuum chambers for more than a decade and we still don’t know everything and are learning every day. We are certainly not perfect, nor are we without faults - no one is. We just wanted to take this time to show you that we take the utmost pride in our work, which is not something very common nowadays in our manufacturing culture and climate. Speed and profit quickly take over quality and robustness and reliability. Fortunately, there is no “half-assing” here at Sanatron. One of our competitive advantages is that we care about our clients. When we make something for you, we put in a lot of effort to ensure that what we deliver will work as intended and will meet and exceed expectations. If you are looking for a cylindrical chamber of utmost reliability and quality, please feel free to contact us.

Did you know that we carry a many more products?

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers