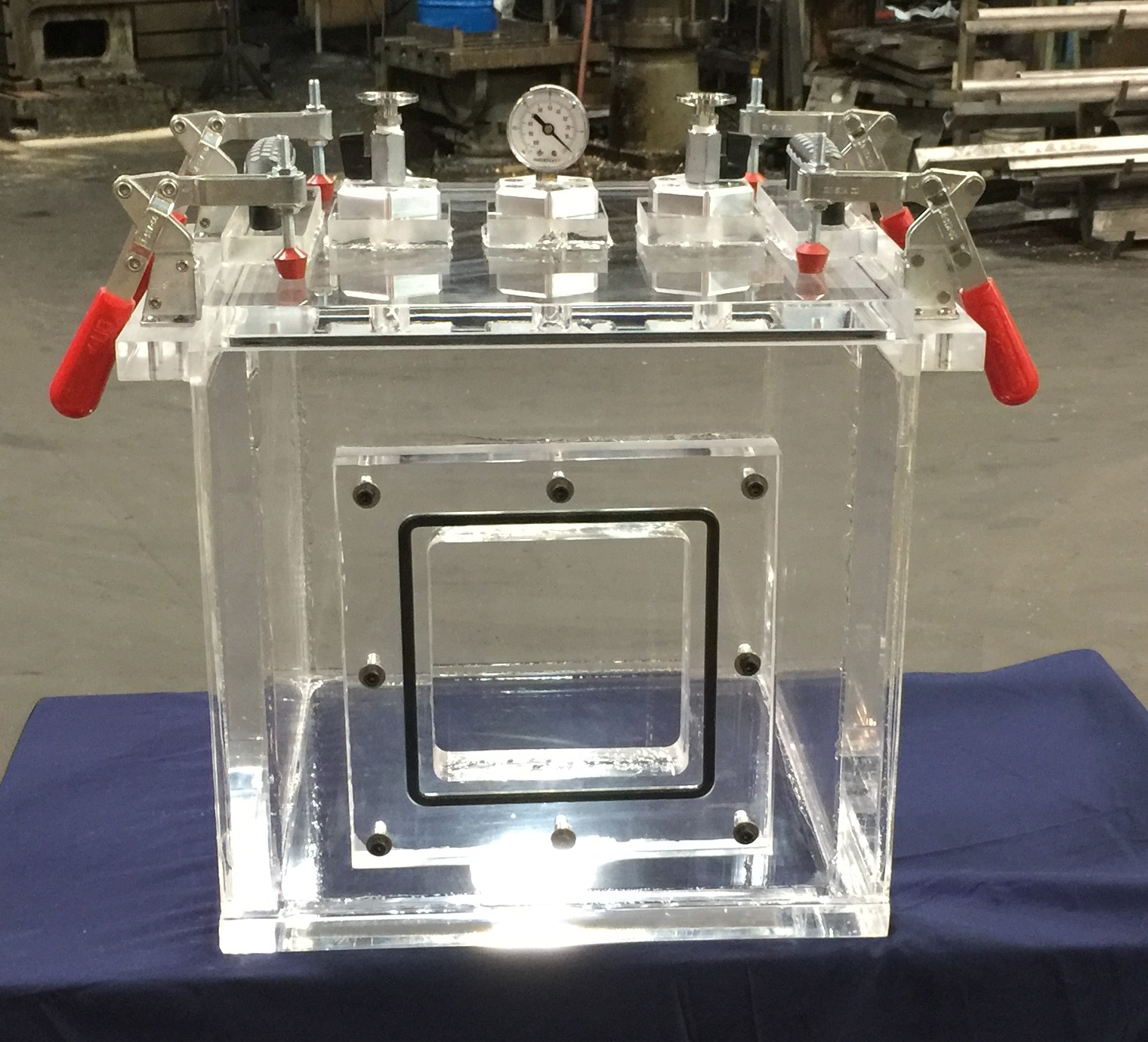

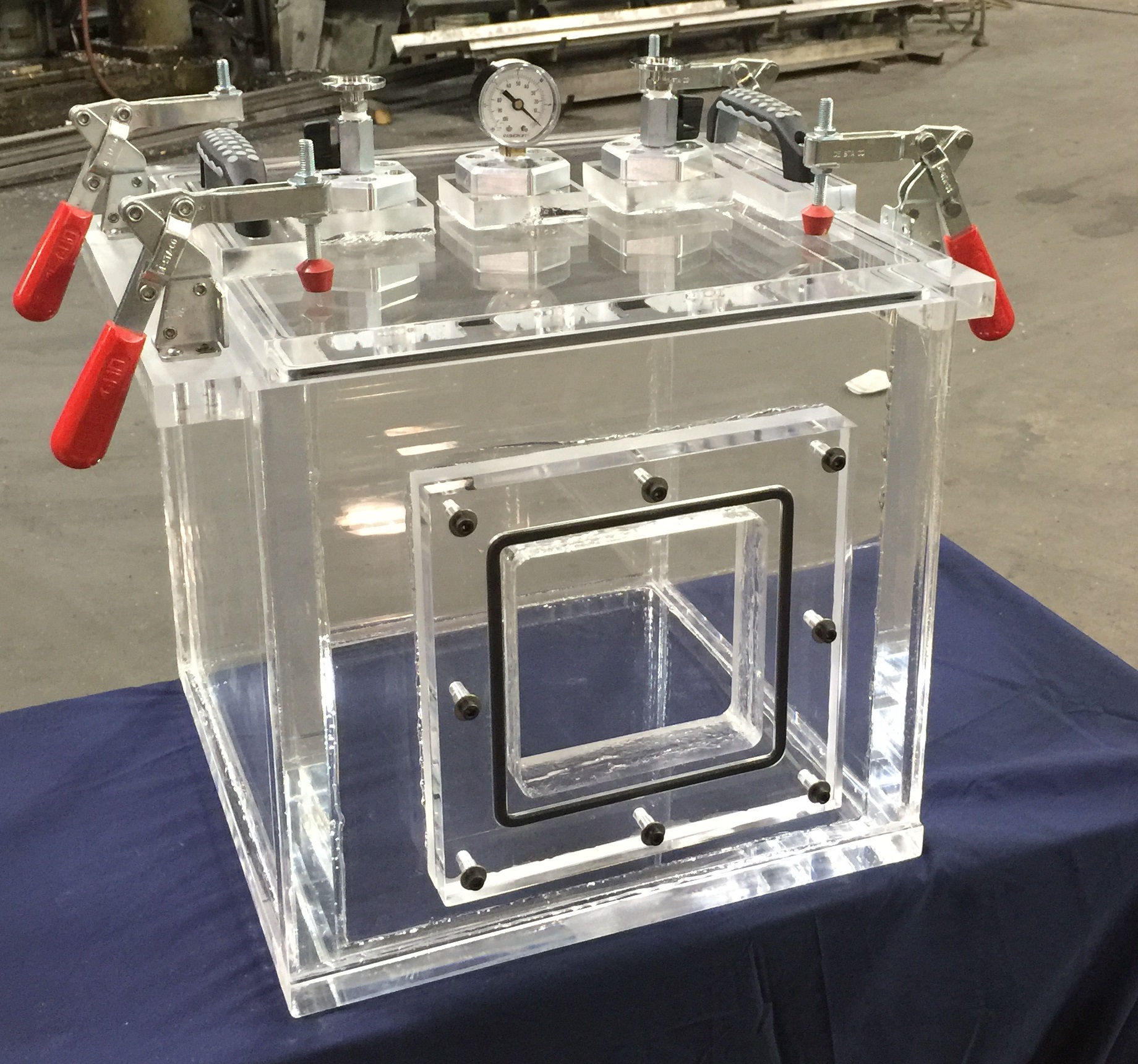

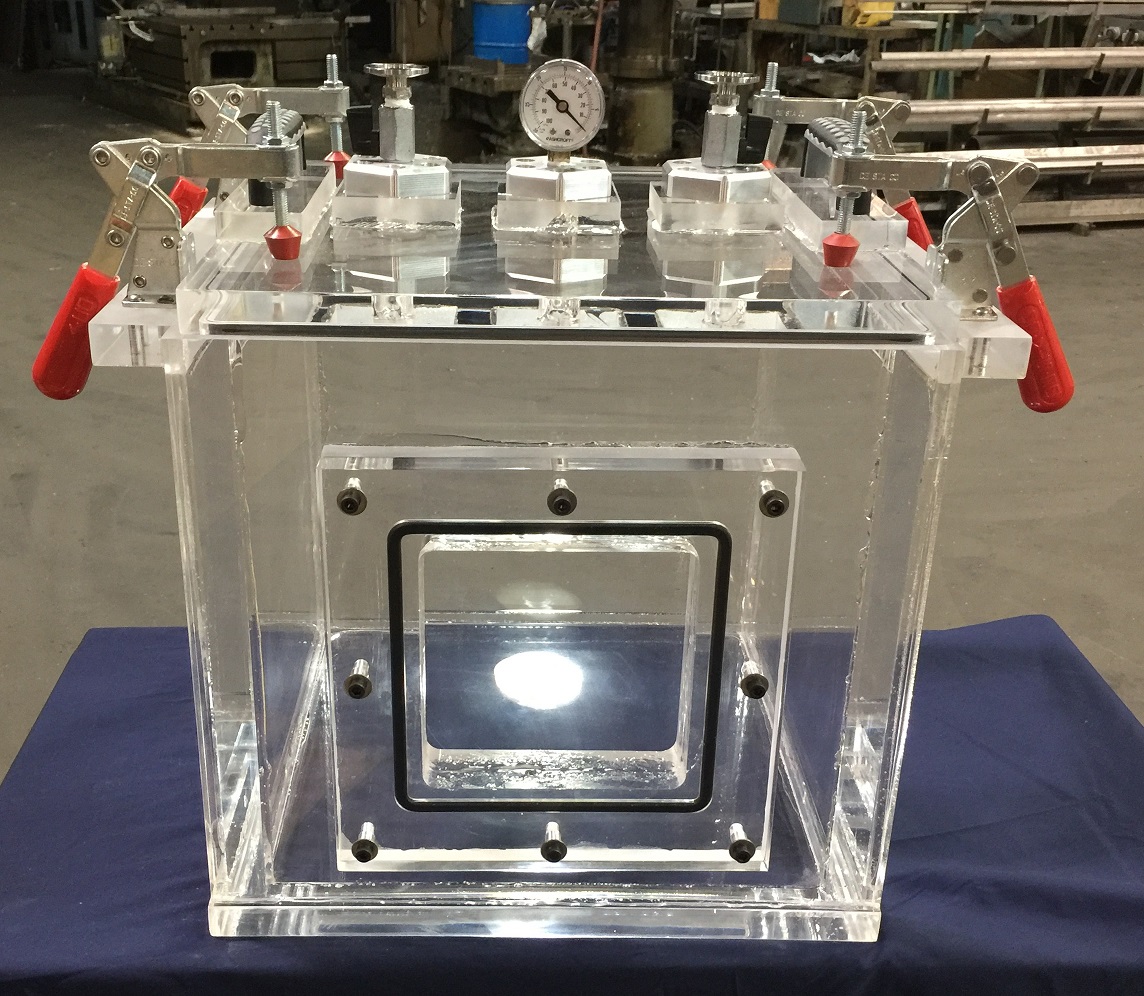

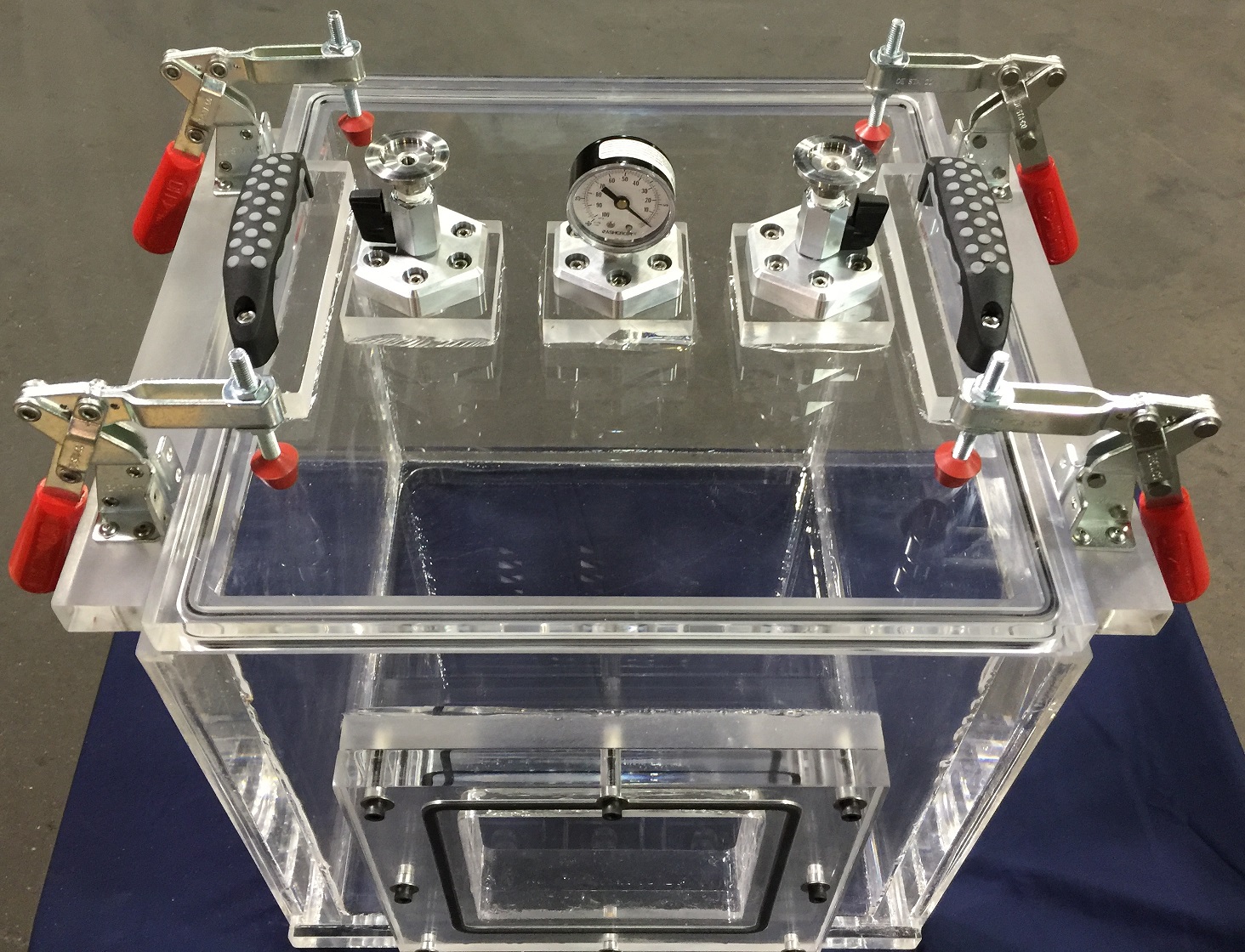

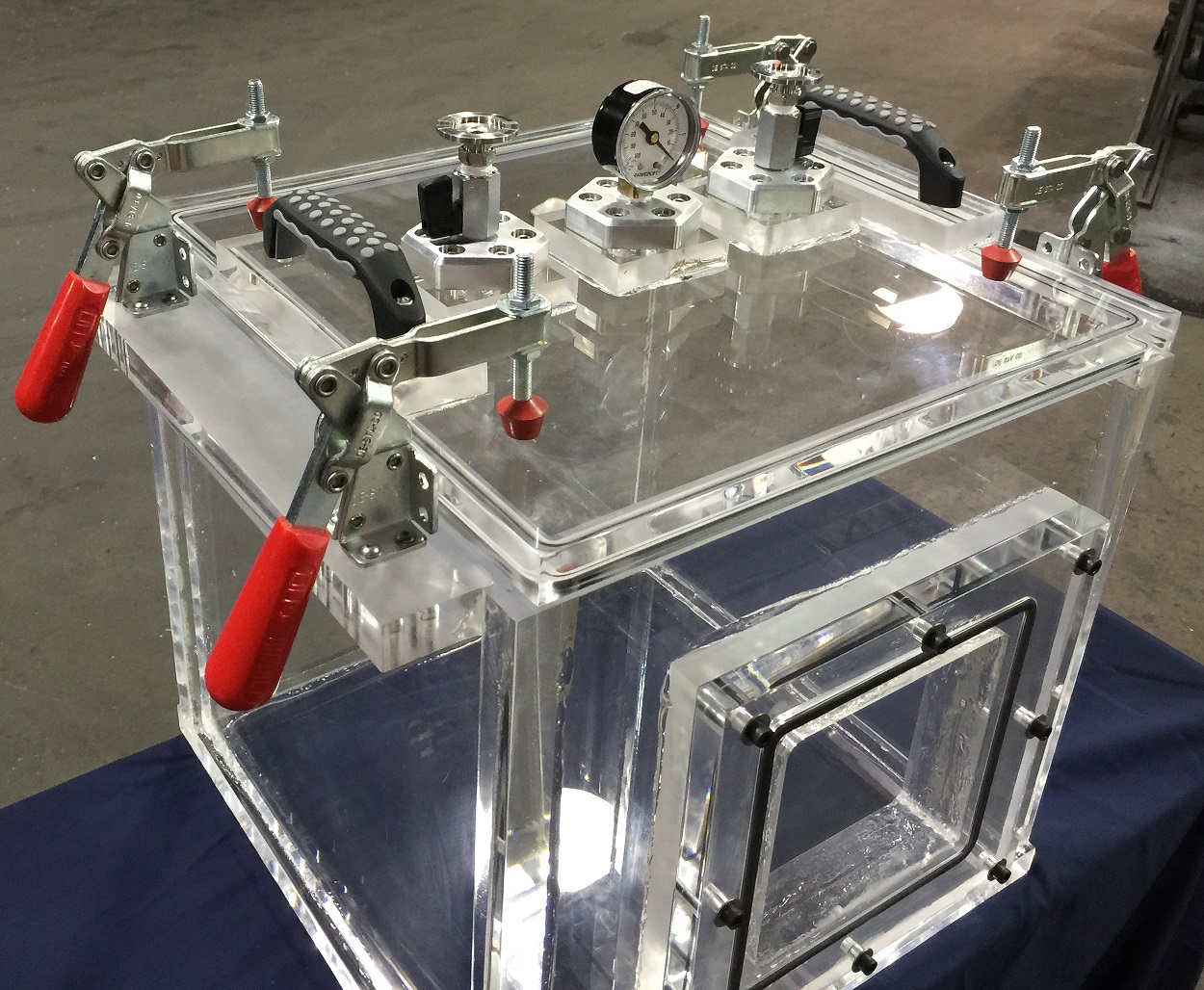

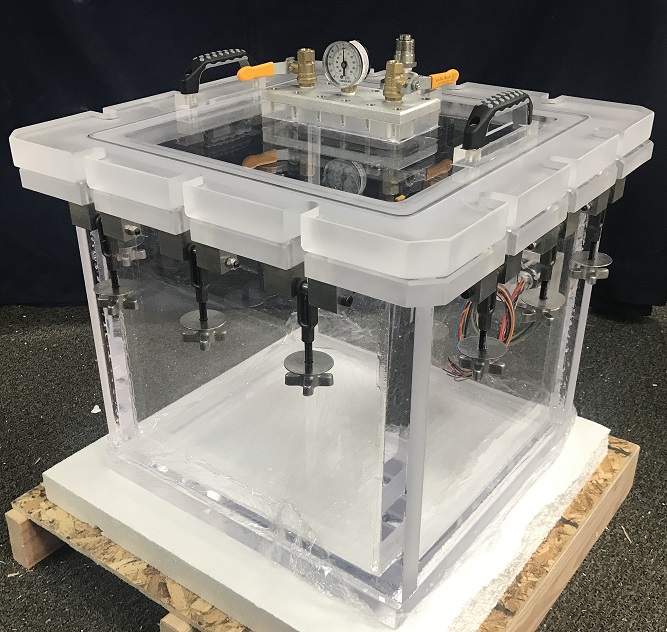

Modified 14 inch Cube Vacuum Chamber for Degassing

This custom job was a modification to our standard acrylic vacuum chambers. When it comes to working with the Us Military, they want all specs to be met 110% and they want it yesterday. The military does not mess around which is why they came to us since we know how important it is to meet specs and ship fast.

They did not tell us what it was for, but what they did tell us is that they needed a blank plate (which they would modify on their end) with fastening capabilities and a square hole on one side of our chamber. What you see here is a slightly modified version of our existing chambers.

Some of our Popular Items

We are an Engineering Excellence Company. You should check out some of our other items we carry; click on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers