Vacuum Package Testing System Table Top

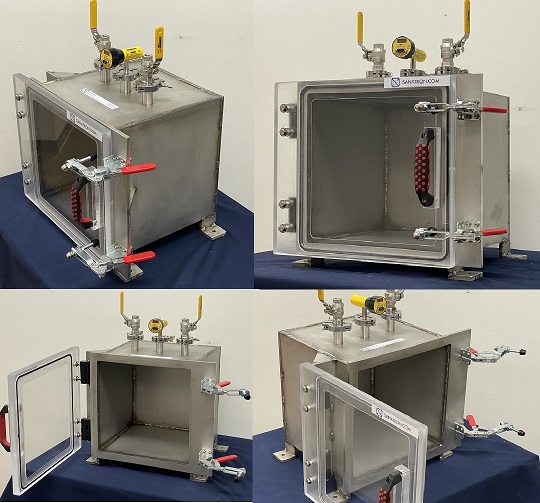

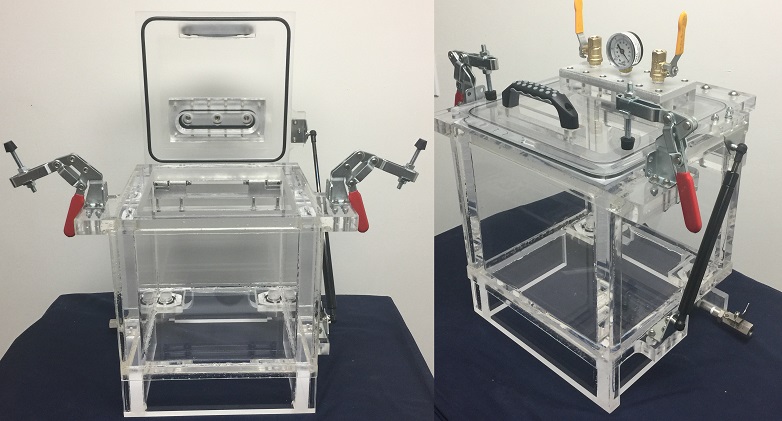

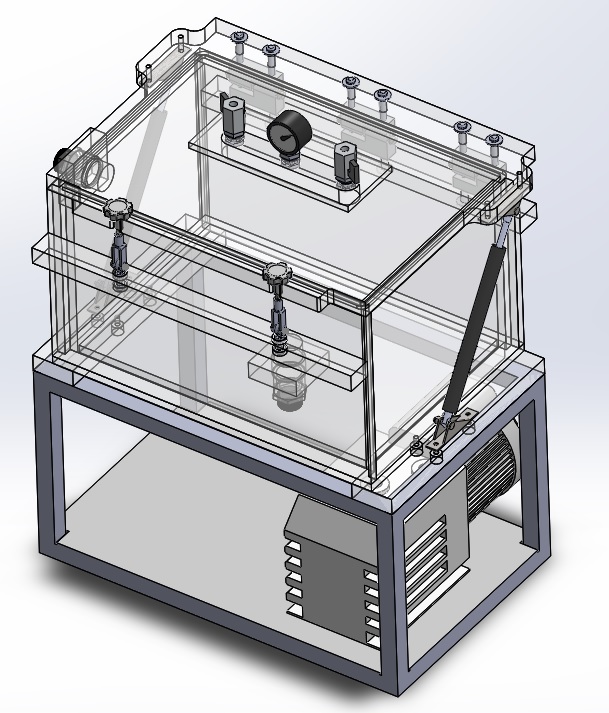

This is a fully assembled, table top vacuum package testing system. When you receive this, all you have to do is plug in the vacuum pump and the vacuum controller, and you are ready to vacuum test your packages. The Vacuum Chamber dimensions are 18 inch wide, 12 inch Deep, and 10-inch High. The vacuum chamber has a drain valve at the bottom wall of this tank. The lid is hinged and opens fully, beyond 90 degrees. The lid also has a gas support spring that will hold the lid open and prevent it from slamming back when the operator is loading up the vacuum chamber. As a standard, each lid come with two clamps and a lid handle.

On the lid, you see a digital vacuum gauge. And two solenoid vacuum valves. One valve is connected to the vacuum pump. The other solenoid valve is the vent valve. There is also a manual venting valve that is kept closed. The digital vacuum gauge and the two solenoid valves are connected to the vacuum controller. The chamber is fully operated by the vacuum controller which can operate in manual mode where each individual valve and vacuum pump is toggled on or off. It can also be run in manual mode where the user sets the target vacuum, or the equivalent altitude, and the hold/dwell time – press start to start the cycle. The controller will pump the chamber down to the target altitude, hold it there for the set dwell time, and went after the dwell time has elapsed. Below the vacuum chamber is the rotary vane vacuum pump capable of reaching about 2 Torr of absolute pressure. The vacuum pump is equipped with an oil mist eliminator exhaust filter. In addition, it is also equipped with a vacuum pump protection valve that will close if water is pulled in the vacuum line.

This system allows the user to perform two types of vacuum package tests: 1. Dry vacuum package test and 2. The wet or water submersing vacuum package test. During the dry vacuum package test, the test specimen is placed into a dry vacuum chamber and a vacuum is pulled in order to look for seal integrity failures. A water submersion package leak test is when the tank is filled with water, the test specimen is placed into the water bath, the lid is closed and the test specimen is pushed below the water line. Vacuum is pulled and the operator will look for air bubbles emitting from the test specimen indicating a leak. In this video, we performed an altitude simulation test where we brought the package to 35,000 feet of altitude, held it for 1 min, and vented the chamber. This was to determine if the package will survive an accidental depressurization at 35,000 feet. Fortunately, the package did not pop open during this test and we are happy to inform you that this is a PASS.

We have many more resources on our website that you should check out

Our clients prefer to work with us because we are Experts in Vacuum Science and Technology. There is a tremendous amount of valuable resources and information regarding vacuum systems and vacuum technology; check them out by clicking on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers