Vacuum Simulation of Aerospace Parts using a two-door Chamber

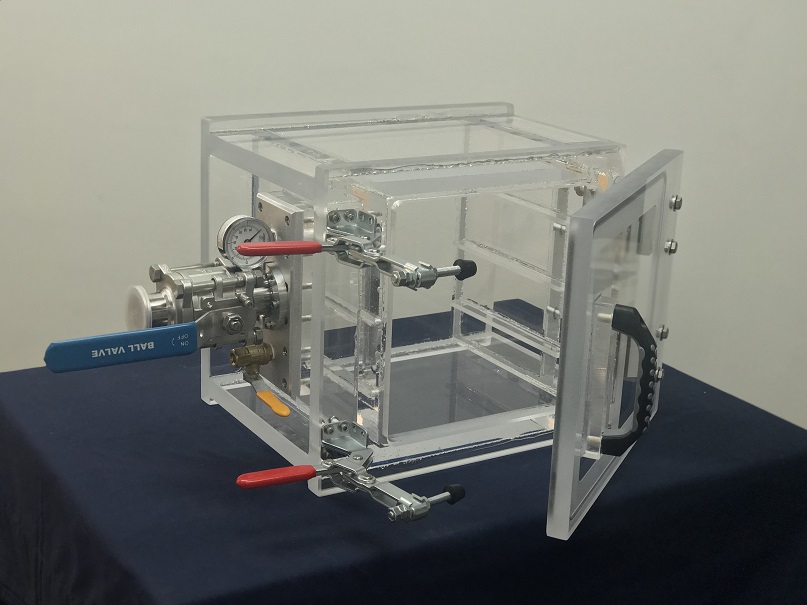

A Vacuum Chamber is vital when it comes to testing of aerospace equipment and parts. The obvious reason is because space or anything at higher altitudes will be subjected to a pressure differential as compared to sea level pressures. A vacuum chamber not only allows for performance testing of aerospace parts, it also allows for quality and leak testing of such parts. Acrylic is preferrable because acrylic is fully transparent allowing for full view of product during the vacuum test.

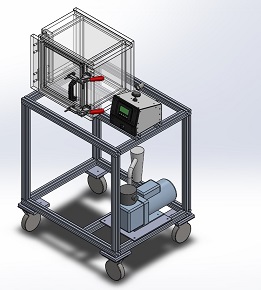

An aerospace company had a need to both leak and quality test the parts they were making. Our vacuum chamber was used two-fold; 1. To create a pressure differential (vacuum) and leak test the parts. 2. To create a vacuum and performance test their parts to see how these will behave and perform at different vacuum levels. In order to improve production thruput and efficiency, another requirement they had is that the chamber needed to be accesses from two opposing walls. What you see here is a 20-inch inside dimensions, acrylic vacuum chamber with two-doors. One door is placed on the front wall while the other is placed on the rear wall. Both doors are hinged and front loading. The means that the vacuum chamber can be placed on a table top and accesses from both directions of the table. When the first operator places the aerospace part into the vacuum chamber, and after the vacuum test has successfully completed. The aerospace part can now move onto the next step. The second operator can now open the door from the other side and take out the aerospace part. The business manager is happy with the time savings because the second operator does not have to walk around the table to reach the part after the test has completed. The quality manager is happy too because the part will travel less distance and the risk of dropping or mishandling the part has been reduced.

If you are looking for a custom vacuum chamber or a custom vacuum system, you are at the right place. We have been making vacuum chamber systems and our customers happy since 2008. Contact us to find out how we can help you.

We have many more resources on our website that you should check out

Our clients prefer to work with us because we are Experts in Vacuum Science and Technology. Check out some of our other items we carry that you can combine/integrate with your systems or projects.

Complete List of Articles Related to Acrylic Vacuum Chambers