Vacuum Testing of Aerospace Equipment implementing Custom Chambers

A large aerospace company and a DoD contractor requested a quote from us for a custom vacuum tester to be utilized for the vacuum testing of various Aerospace Equipment Parts on their production line. All of their items were solid and ridged containers, cubic, square, and cylindrical which needed to be tested by following the vacuum submersion testing technique.

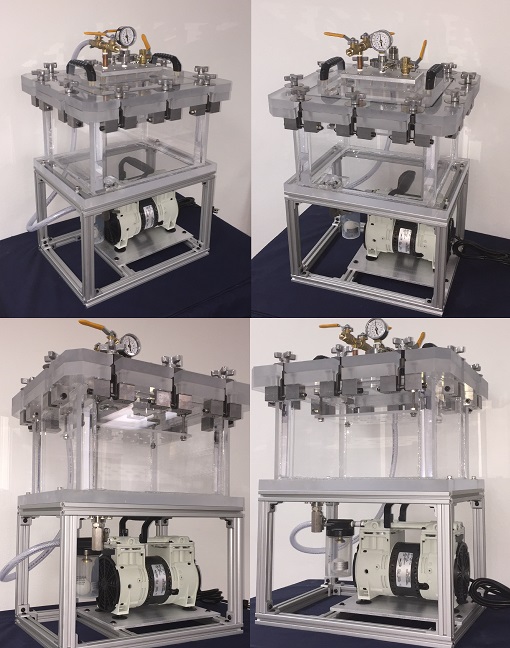

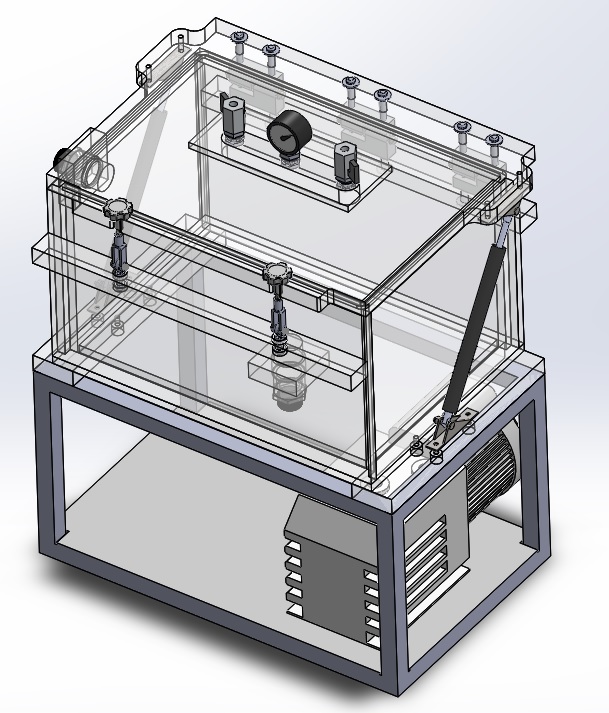

With that said, this test does require an extra step in that the part must be under vacuum when it is above the water level. As soon as the target vacuum is reached, the part is dunked under water. Once the test is completed, the part is lifted above the water level one more time before the chamber is vented. The solution we provided was to modify our standard Vacuum Bubble Leak Tester to accommodate all our client’s requests. The vacuum chamber is about 12-inch Wide, 10-inch Deep, and about 8-inch High. The vacuum is generated by a standard duty, rotary vane vacuum pump. The rotary vane vacuum pump comes with an oil mist eliminator, exhaust filter that will minimize or prevent from oil mist being exhausted into it’s surroundings. Furthermore, the rotary vane vacuum pump also comes with a vacuum pump protection valve which will close off if water is present in the vacuum line.

The chamber is top loading with a hinged lid. On the lid is the vacuum gauge, the venting valve, and the vacuum valve. Inside the chamber is a plate that can be lifted either upwards or downwards, depending if the testing sample is needed to be above the water line or below the water level. The specimen plate is lifted via the two levers which are connected to the front wall. A vacuum rotary feedthrough will translate rotary power from the outside of the chamber to the inside of the chamber without compromising vacuum during operations. The levers can either swing inwards and lower the tray or swing outwards and lift the tray. We also have a fully automated pneumatic version that does not use levers by four pneumatic cylinders to drive the tray upwards or downwards. If you are looking for a vacuum dunk test which requires some complex procedures, feel free to reach out to us to discover how we can assist you with you leak testing needs.

Did you know that we carry a many more products?

We are an Engineering Excellence Company. You should check out some of our other items we carry; click on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers