Aviation and Drone Technology Testing Chamber

Drone Technology has been very popular lately and it seems that we have yet to run out of ideas on how unmanned drones can be used in our every day lives. Over the past ten years, we have seen an explosion in drone applications from delivery, photography, reconnaissance, war, investigations, architecture, medical, aerospace, etc… As drone tech improves so does drone Quality control and it becomes crucial to test and retest the operability of each drone in order to confirm that the product meets or exceeds expectations.

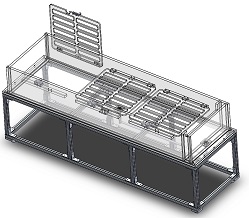

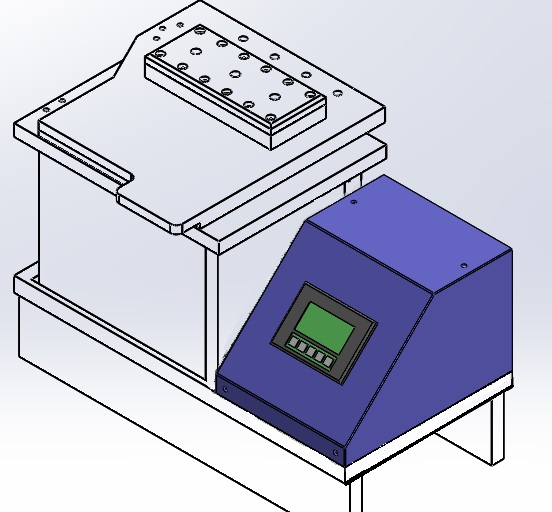

An aviation and drone technology development and manufacturing company contacted us to design and build a testing chamber that will be capable to allow them to quality test various aviation and drone components. What you are looking at are two identical test chambers that we have built for them, but this was actually not the first job we have done for them. Initially they requested a single chamber and then they revised the first design to optimize their requirements which yielded two more identical chambers.

Each chamber has internal dimensions of 12-inch cube. The test chamber has a NW25, blanked off, port at the bottom wall. The bottom wall is also lifted via a skirt by about 5 inches from the ground. Each lid has QTY: 2 x NW40 vacuum valves. We don’t really know why the chamber has QTY: 2 x NW40 vacuum valves because it does seem excessive. We asked, and they told us because the NW40 vacuum valve has in Internal Diameter of about 1.375 inch which is what they were interested in. The lid also has two more valves that have a NW25 port adapter. One of the valves has a filter element connected to it. This is something we don’t usually see because this filter is connected to a rotary vane vacuum pump exhaust and not to a valve which is connected to a testing chamber. So we asked and they did not tell us why, this was something proprietary to their test. The lid also has a dial vacuum gauge and two lid handles allowing for a fully removable lid. The lid is clamped down via QTY: 4 x lid clamps. Also, everything that is in contact with the inside of the test chamber is stainless steel. Contact us if you are looking to build a custom test chamber for your next project.

We have many more resources on our website that you should check out

We make Robustly Designed and Quality Engineered Systems. What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers