Biotech Vacuum Chamber

Biotech Instruments must undergo vigorous Quality Control (QC) testing prior to product release. A vacuum chamber is an ideal tool as it allows testing of biotech products and instruments under controlled conditions to simulate real-world scenarios. Biotechnology incorporates a wide range of industrial and scientific processes ranging from drug development, genetic process engineering, and medical devices. It is critical to ensure proper fit and function of biotech products.

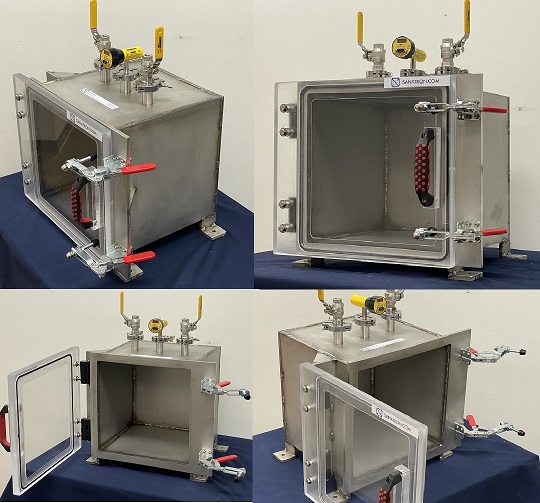

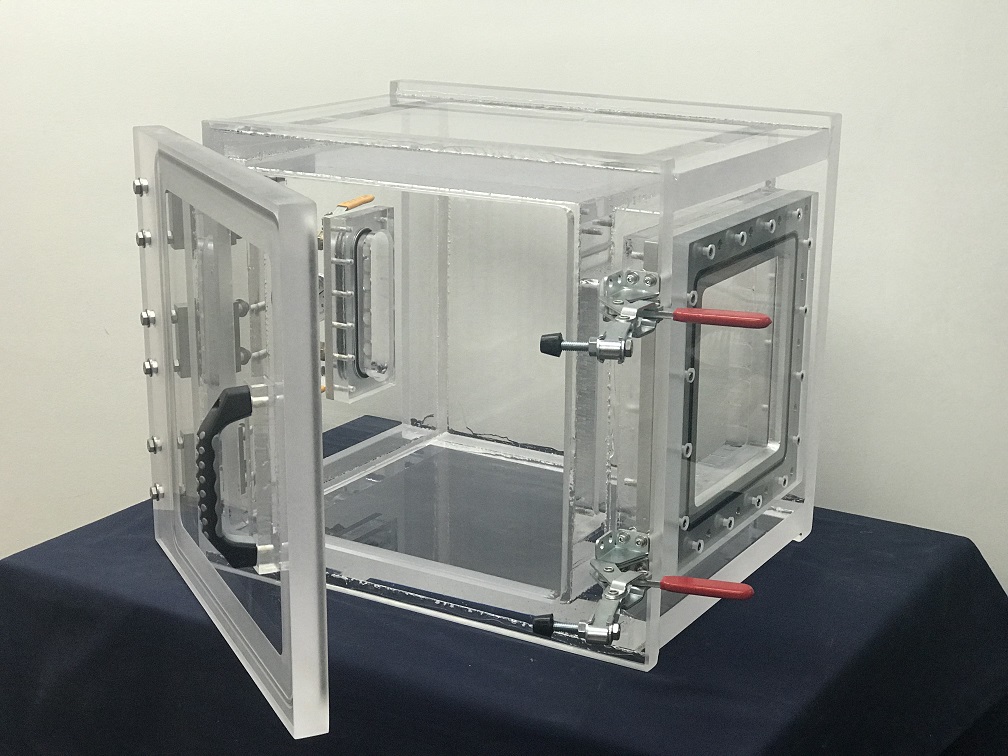

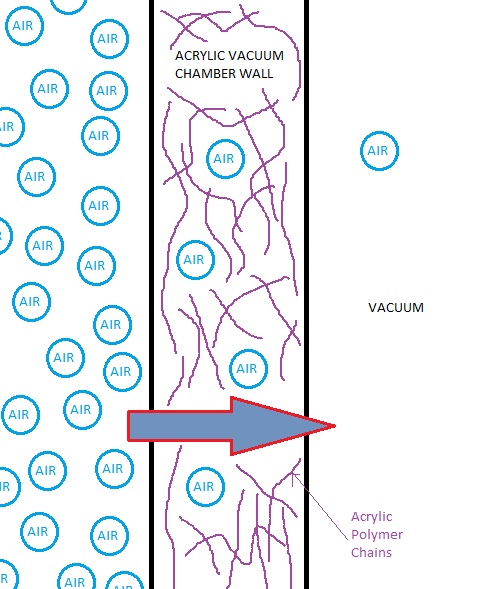

A biotech instrumentation manufacturer had a need for a vacuum chamber with BNC Coaxial vacuum feedthroughs which were fed into the vacuum chamber and connected to the biotech instrument while it inside the vacuum chamber and under vacuum. The coaxial connector was present on the inside and outside of the vacuum chamber. The coaxial cable was then connected to the outside of the vacuum chamber and ran to the data acquisition unit controller (synthesizer). The requirement was to hold the biotech instrument under controlled vacuum conditions to allow for real-world instrument testing. The vacuum chamber had to be large enough to allow the instrument to fully fit into the vacuum chamber. You are looking at a vacuum chamber that is 24 inch Wide, 16 inch Deep, and about 10 inch High. The lid is fully removable. There are a total of four lid clamps and on the lid there is a vacuum gauge and two vacuum valves. All our acrylic vacuum chambers are hermetically sealed and will hold vacuum for an extended period of time. During our tests, in this specific case, the vacuum was pulled to 0.500 Torr absolute and the vacuum valve was closed. After 24 hours, the vacuum level was 4.2 Torr. After one week, the vacuum level 4.63 Torr. The chamber lost about 0.43 Torr in a span of seven days. A week of vacuum holding was all that was required in the specific test, but we are fairly confident that this vacuum chamber would be able to hold vacuum (with a small drift) for months, even years.

Our engineers with decades of combined experience in vacuum technology will be able to customize your vacuum chamber to meet and exceed your specific requirements. If you are looking for a biotech vacuum chamber to perform high precision and high quality product testing, we have standard chambers that you can chose from or we can customize to meet your detailed requirements. Contact us.

We have many more resources on our website that you should check out

We make Robustly Designed and Quality Engineered Systems. What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers