Container Closure Integrity Testing Chamber

Container Closure Integrity Testing is a critical Quality Control process used mostly by the pharmaceutical and biotech industries and many food industries. This quality control process ensures the safety and quality of closed containers and its ability to stay closed and maintain seal integrity throughout the life of the product. There are several ways to and methods used in the Container Closure Integrity testing. One of the most effective is the use of a vacuum chamber for several reasons. First, a vacuum chamber can be used to perform Dye Ingress Testing. Second, a vacuum chamber can be used for Vacuum Decay Testing. Third, a vacuum chamber can be used for heat seal integrity testing. And fourth, a vacuum chamber can be used as a vacuum bubble leak test.

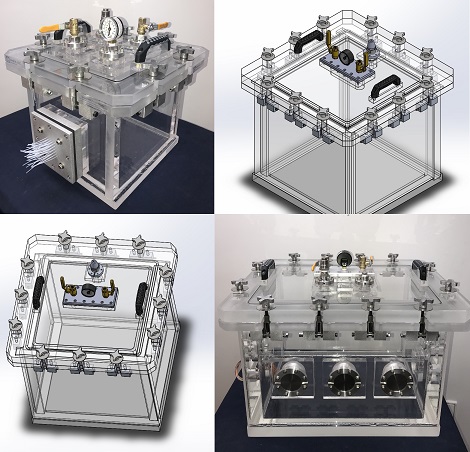

A pharmaceutical company reached out to us because they wanted to have the ability to perform Container Closure Integrity Testing on a wide range of their products. They specifically asked for a vacuum chamber because of the four ways a vacuum chamber can be utilized in such test. We provided them with a cost-effective solution which we think should be present in any pharmaceutical company which is our top loading, spring supported hinged door; which keeps the lid open hands free, allowing the operator to operate the chamber with both hands without having to worry about the lid slamming back. The chamber inside dimensions are 10 inch Wide, 10 inch Deep, and 10 inch High. As a standard, each of our vacuum chambers comes with a vacuum valve, venting valve, and a dial vacuum gauge.

Various Regulatory agencies will ask you about your Container Closure Integrity Testing Protocols. If you are serious about product quality and are looking for a vacuum chamber to take product quality to the next level, reach out to us to see what we can make for you.

We have many more resources on our website that you should check out

We are an Engineering Excellence Company. There is a tremendous amount of valuable resources and information regarding vacuum systems and vacuum technology; check them out by clicking on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers