Research and Development Vacuum Chamber

Vacuum Chambers are often utilized in research and development ranging from pharmaceuticals, product design, or aerospace. Many potential customers reach out to us asking us if this or that is doable with a vacuum chamber. The answer is usually yes, the vacuum systems industry is a mature one and what you may think is something that cannot be done or may be difficult to do, it may have already been done. Most of our builds are custom builds made specifically to customer requirements.

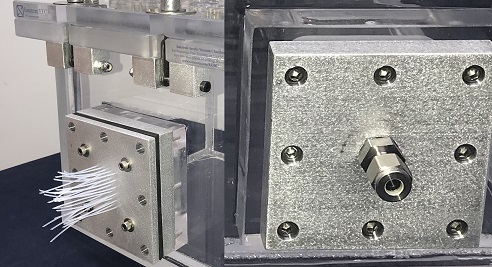

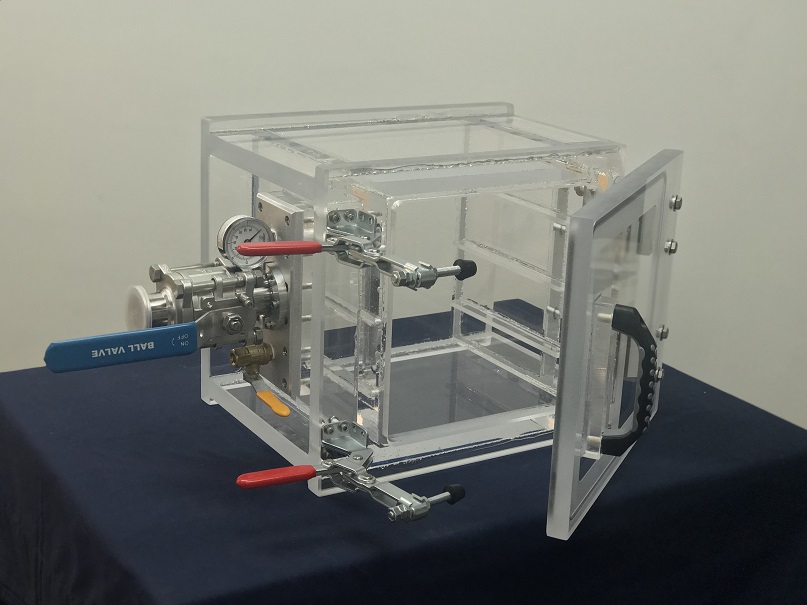

One example is the vacuum chamber you are looking at. This is a top loading, hinged top lid. It has this weirdly machined plate that is difficult to see, since the acrylic is crystal clear, inside the vacuum chamber. You will notice several holes of various patterns and different sizes. These holes are made to accommodate the part that our customer is researching and developing. Furthermore, you will notice two Coaxial Vacuum Feedthroughs on the Right wall. There are also two 0.25 inch NPT feedthroughs where the NPT thread is present on the inside and outside. You will also notice several wires of varying gauge sizes present inside the chamber. These wires are connected via a vacuum wire feedthrough. This means that you can run electrical signal, voltage, amperage, or power into the vacuum chamber during vacuum operations without compromising the vacuum.

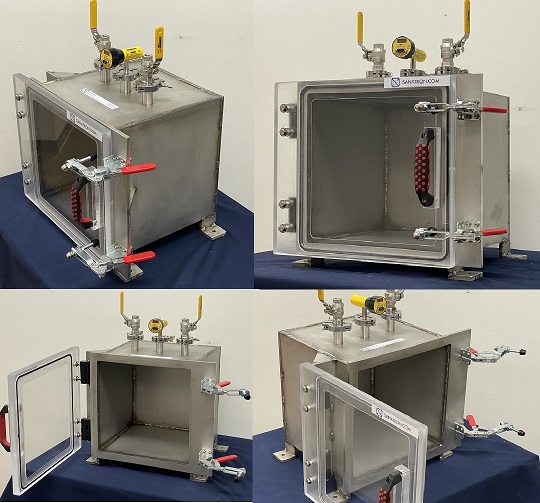

As you can see, looking at the Digital Vacuum Gauge, the chamber is currently at 96 milliTorr of absolute pressure. This equals about 99.987% vacuum. We have pulled this much vacuum as our customer required this chamber go beyond 100 milliTorr. If you are looking for a high performance vacuum chamber for Research and Development, contact us to find out why were are the industry leading vacuum chamber manufacturer.

Did you know that we carry a many more products?

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). There is a tremendous amount of valuable resources and information regarding vacuum systems and vacuum technology; check them out by clicking on the links below.

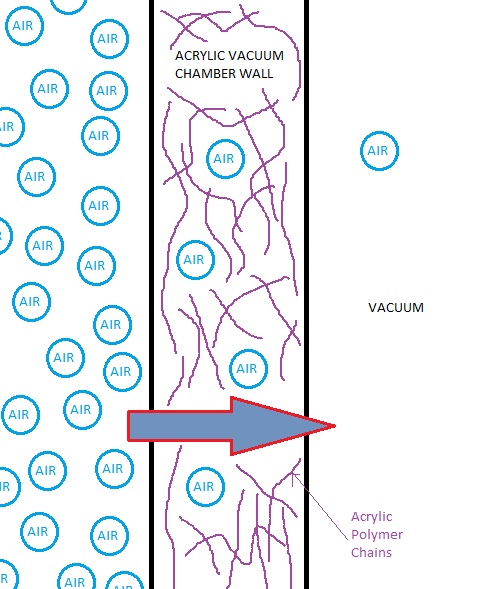

Complete List of Articles Related to Acrylic Vacuum Chambers