Stainless Steel Vacuum Chamber

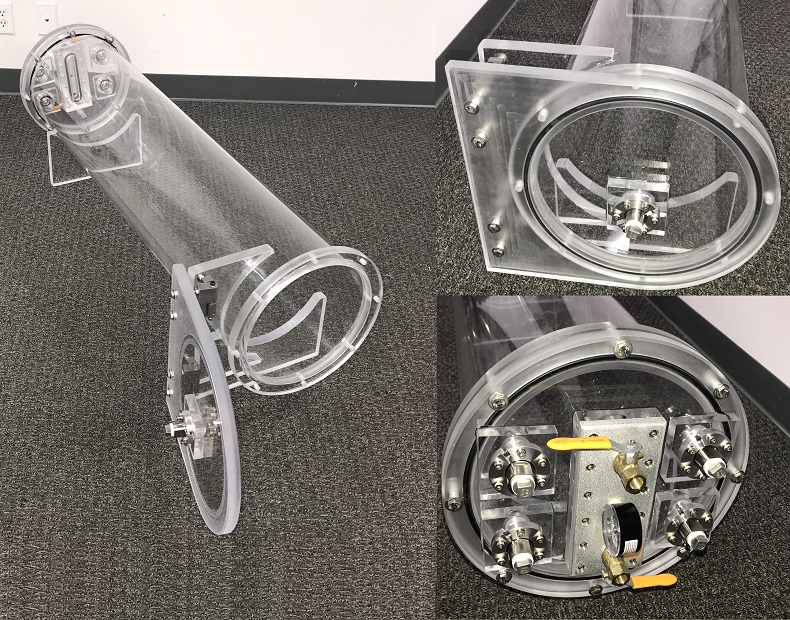

Our experience and capabilities range from clear acrylic, to aluminum, to stainless steel vacuum chambers in cube, square, cylindrical, and weird shapes. Over the years, we have had the privilege to work with all branches of the US Government, most of the Russell 2000 companies, and most of the companies listed in the S&P500. When it comes to vacuum systems, we have seen it all.

There are several reasons to choose a stainless-steel vacuum chamber. The main reason is that stainless steel will allow for a much greater vacuum performance over acrylic. In fact, all high vacuum systems use stainless steel vacuum chambers. Another reason to go with a stainless-steel vacuum chamber is that stainless steel is capable of higher operational temperatures. The maximum temperature of a stainless-steel vacuum chamber is in the order of about 350 degrees Celsius. Stainless steel is also used because it is resistant to alcohols, thinners, and solvents and unlike acrylic, it will not craze or blemish during exposure to the aforementioned chemicals.

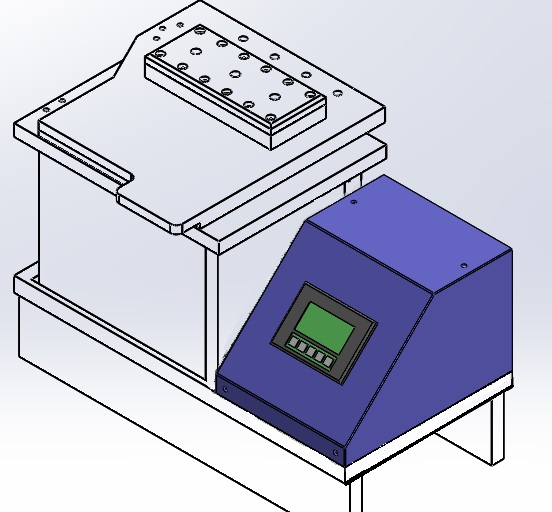

You are looking at a 12 inch Wide, 12 inch Deep, and 12-inch-High Stainless Steel Vacuum Chamber with a clear acrylic front door. The chamber door has two toggle lid clamps, one lid handle, and two door hinges. The door will fully open beyond 90 degrees enabling fully loading operation. The chamber has QTY: 4 x mounting feet with 0.5-inch Holes at the bottom. On the top wall, you will see a QTY: 3 x NW25/QF25 Quick Flange 25 ports. Two of these ports are populated with a stainless steel 0.5-inch NPTF valve. The middle port is connected to an Instrutech stinger CVM Vacuum Gauge. This vacuum gauge is capable of measuring and displaying absolute pressure in Torr and millitorr in three significant figures and the range is from ambient to 0.001 Torr or one millitorr. If you are looking for a robust and quality made stainless steel vacuum chamber, contact us to find out what we can do for you.

Similar Items

Our clients prefer to work with us because we are Experts in Vacuum Science and Technology. What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers