Vacuum Chamber inside another Vacuum Chamber like Chamberception

Can you build a vacuum chamber inside a vacuum chamber? Yes, space permitting, we make place a smaller vacuum chamber inside a larger vacuum chamber have them operate at different vacuum levels. This is possible as long as there is sufficient space to place the o-ring so that a vacuum seal can be achieved.

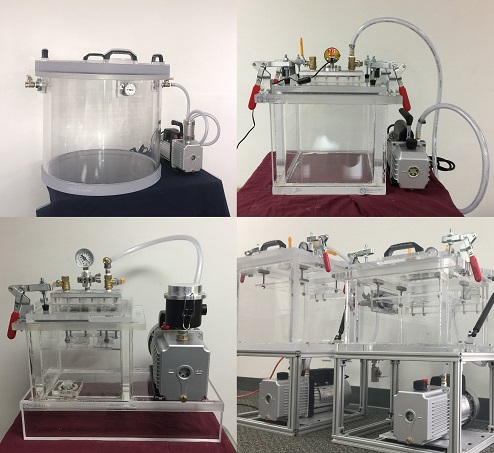

We are used to all kinds of interesting requests when it comes to customizing our products so when we were asked to modify an existing vacuum chamber by adding another vacuum chamber to it, we jumped right into this opportunity. Our customer wanted to create a seal between these two chambers so that the vacuum levels can be set independently for each vacuum chamber. The modification process entailed creating a lid with QTY:2 x O-Rings. The smaller chamber would connect to the smaller O-Ring placed on the inside diameter. The larger chamber would connect to the larger o-ring. The sizes for the smaller chamber are about 11 inch outside dimensions while the size of the larger chamber are about 15 inch outside dimensions. There is about 1.5 inch of space between the walls. Another requirement was that we had to create a way to pull a vacuum on both chambers. This was easy for the larger chamber because all we had to do is place some valves on the outside wall and viola, we were all set. However, the challenge came from creating the ability to pull vacuum on the smaller chamber which was inside the larger chamber. We thought to just add the valve onto the top lid center and connect to the smaller chamber. We were not able to do this because another important requirement was to make sure that the top of the lid is clear. This was because and X-Ray beam was being shot from the top towards the bottom of the chamber. In order to get good results, nothing could be placed in front of the X-Ray beam. What we came up with as to drill a diagonal hole while placing the vacuum gauge and vacuum valves all the way towards the edge of that lid. This is why the plumbing is off to the side. This project was a success and our customer has been very happy with what we did for them.

Vacuum Insulated Tank Some time later, we were contacted by another company who heard that we are the experts in making chamberceptions happen. They had another idea: They wanted to vacuum insulate the perimeter of their acrylic tank. Well, we admit that this is not a vacuum chamber withing a vacuum chamber by rather a vacuum insulated tank. Since this tank was on the larger size (as can be seen in the lower image, just below the yellow line) measuring a length of 48 inch depth of 12 inch and a height of 12 inch, thicker acrylic had to be used in order to prevent buckling and to increased chamber robustness at a great Factor Of Safety. We used 2 inch Thick acrylic for the outside and inside walls of both ends of the chamber making this piece incredibly heavy and bulky. But it got the job done. We lowered the inside tank into the larger chamber with a crane where the O-Ring was placed on the flange of the larger chamber. The weight of the inside tank alone was sufficient to compress the O-Ring and generate an air tight seal. We use about QTY: 12 x bolts to connect these two tanks just so that we keep them connected and in place. Are you looking to build some custom vacuum chambers and not sure if it a crazy request or if someone will even listen? Well, look no further! Custom requests is something that we are happy to do as it takes us away from the standard builds we make. More importantly, it gives us the opportunity to serve you and to provide tremendous value to our customers and to the vacuum industry as a whole. Contact us if you have a custom request for a vacuum chamber.

Some of our Popular Items

We make Robustly Designed and Quality Engineered Systems. Check out some of our other items we carry that you can combine/integrate with your systems or projects.

Complete List of Articles Related to Acrylic Vacuum Chambers