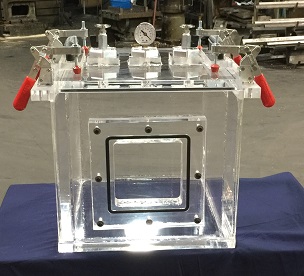

Vacuum Panel Plate with Various Vacuum Feedthroughs

Our custom-made vacuum panel plate will come in handy in the future. Let us explain. When our clients are getting a vacuum chamber or a vacuum system from us, they sometimes do not know what vacuum feedthroughs such as Wire, USB, Thermocouple, D-SUB, Ethernet, Liquid and Gas, etc. they may need in the future. A dilemma arises if a vacuum chamber without the vacuum panel plate has been purchased. This means that in order to add vacuum feedthroughs to the vacuum chamber, the actual vacuum chamber will need to be modified. This can be done either by having the customer drill into the chamber, this is not recommended because DIY vacuum chamber modification will create risk of product damage and or personnel injuries. Another option is to either order in house service and or ship the chamber back to manufacturer for modifications. Both will result in downtimes and ore delays.

The best option is to order a vacuum panel plate at the time the actual vacuum chamber is ordered because the vacuum panel plate can be modified or a new panel plate can be made and shipped to the customer without having to modify the actual vacuum chamber or having to send the vacuum chamber back for modifications. Hence saving time and money.

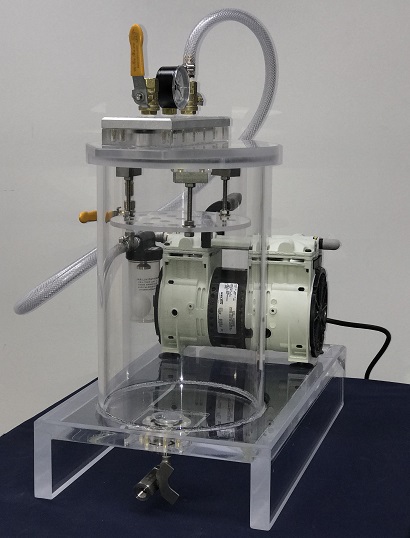

What you are looking at is a vacuum panel plate that we made for our client. A year or so after they purchased a vacuum chamber from us, they requested a couple of feedthroughs to be installed on the vacuum chamber. Fortunately, they had the blank panel plate. What we did is we made them another panel plate and installed the feedthroughs they wanted. They wanted a QTY: 8 BNC Vacuum Feedthroughs, a QTY: 1 x D-SUB 15 pin Vacuum Feedthrough, and QTY: 4 x pair, Type-K thermocouple Vacuum Feedthroughs. Once our customer received the custom plate with the feedthroughs they wanted, they simply removed the blank plate and installed their new plate within minutes. If you are looking to get a vacuum chamber but don’t know what vacuum feedthroughs you will need in the future, contact us to see how we can help you hash things out.

WAIT! Take a look at similar Items you may like…

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). You should check out some of our other items we carry; click on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers