Water Submersion Leak Test using Custom Internal Pressurization System

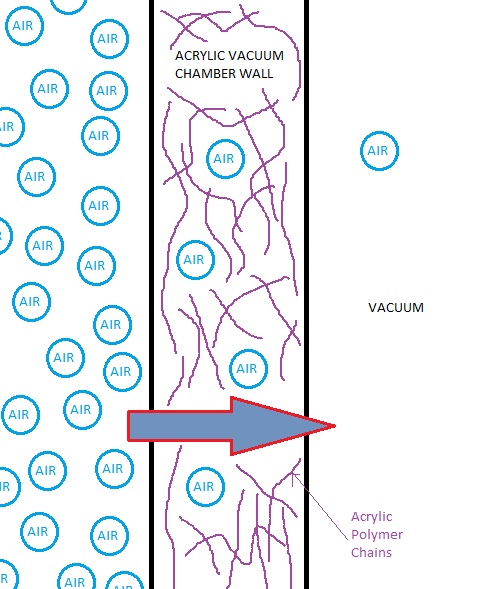

The principle of the water submersion bubble leak test is the same. Create a pressure differential between the inside of the test specimen and the outside of the test specimen. If a leak is present, the pressure differential will drive the air through the leak path. If the test specimen is submersed under water, and there is a leak, it will be visible via bubble emission. There are two ways to create a pressure differential. The first one is to decrease the pressure outside of the test specimen. This is done by placing the test specimen inside a vacuum chamber and pulling a vacuum. The second one is to internally pressurize the test specimen while leaving the pressure outside of the test specimen at ambient pressures. The result is the same: if there a leak, it will be detected via bubble emission.

There are several advantages to internally pressurize the test specimen. One advantage is that unlike the vacuum bubble leak test, an internal pressurization line will provide a constant flow of air into the specimen allowing the operator more time for testing. This is not the case for a vacuum bubble leak test as the volume of the test specimen is limited and once all the air has leaked out of the test specimen, no more air bubbles will be visible even though a leak is present. Another advantage is that a internal pressurization submersion leak test will allow for leak testing of porous material since the air pressure can be controller much better at 0.5 psi. A third advantage is that a larger pressure differential can be achieved because the test specimen can be pressurized to 120 psi and beyond – this is not the case for a vacuum bubble leak test as the maximum pressure differential is about 11 psi. A fourth advantage is that longer test specimen can be tested such as test specimen that are 6 feet long. An example of such long test specimen is a catheter which is inserted into the femoral (leg) vein and guided towards the patient’s heart. A vacuum chamber of 6 feet length may be too costly and too large to handle and therefore a water tank is a better option. A fifth advantage of using a internal pressurization water submersion system is that the test specimen can be rotated and handled during the test. This is not the case when the test specimen is encased and undergoing a vacuum bubble leak test inside a vacuum chamber.

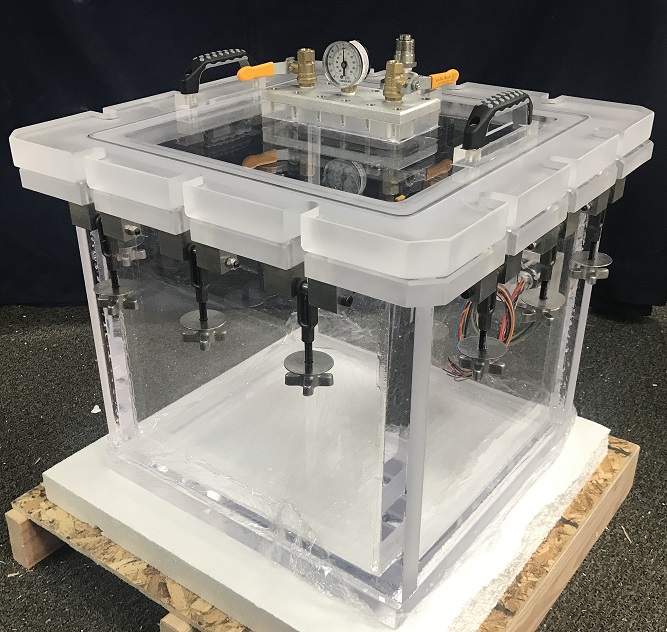

A medical device customer contacted us to build them a water submersion internal pressurization system that will allow them to perform a leak test according to the ASTM F2096 test protocol. Their tank dimensions requirements were 55 inch long, 30 inch deep, and about 12 inch high. They also requested to design and build sample holding clamps, shown in black which will hold the sample connected to the lid. The sample holder will grab the test pouch by the outside seal and hold it on the lid. This will allow the operator to load the testing pouch and clamp it to the lid. The operator then closes the lid and submerses the test pouch under water before applying internal pressure to the test specimen. The ASTM F2096 testing tank also has an overflow tank to the right of the main tank to allow any excess water to drain so that the water doesn’t overflow the actual testing tank. Furthermore, there are two separated lids and each lid has a total of QTY: 3 door hinges and a total of QTY:3 x door clamps. This whole system is situated on 8020 aluminum extrusion table frame structure on lockable swivel casters. If you are looking to build an internal pressurization water submersion leak testing system, look no further and reach out to us to find out why we are the industry leader when it comes to leak testing.

WAIT! Take a look at similar Items you may like…

Our clients prefer to work with us because we are Experts in Vacuum Science and Technology. Check out some of our other items we carry that you can combine/integrate with your systems or projects.

Complete List of Articles Related to Acrylic Vacuum Chambers