Portable Vacuum Test Chamber System with Integrated Pump and Controller Featuring Automated Recipe Selection

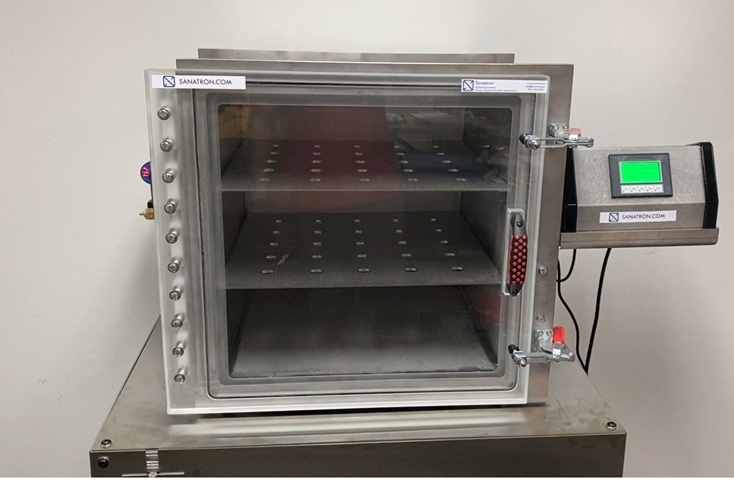

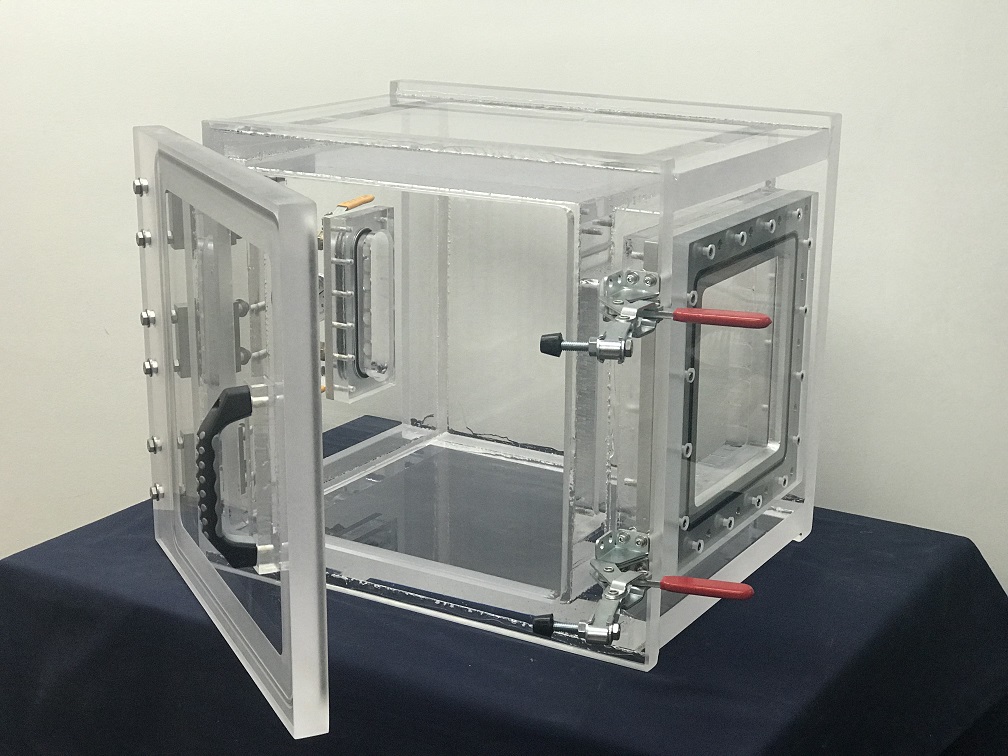

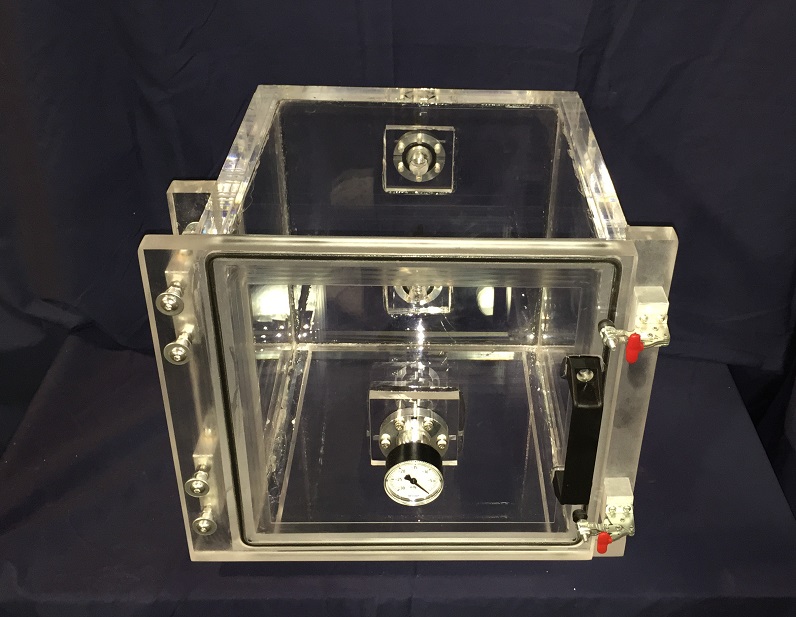

This portable vacuum test chamber system is engineered for professionals who demand precision, visibility, and operational flexibility in a single, self contained platform. At the core of the system is a robust stainless steel vacuum chamber with generous 20 inch cube internal dimensions, providing ample working volume for a wide range of package integrity, material evaluation, and process validation applications. The front loading acrylic door offers full, unobstructed visibility into the chamber throughout the entire automated test cycle, allowing operators to observe deformation, leaks, or other critical events in real time without interrupting the run. This visual access is particularly valuable in regulated environments where confirmation and documentation of test behavior is essential.

Designed with mobility in mind, the entire vacuum system is mounted on a rigid enclosed cart equipped with four heavy duty lockable swivel casters. This configuration allows the unit to be easily repositioned between workstations, production areas, or laboratories while maintaining excellent stability during operation. Whether deployed in a quality lab, pilot production line, or validation area, the system delivers the flexibility required by modern testing environments without compromising performance or repeatability.

Vacuum generation is handled by a high quality oil free piston pump capable of achieving 5 Torr absolute pressure with a maximum airflow of 7 CFM. The oil free design eliminates the risk of hydrocarbon contamination, reduces maintenance requirements, and aligns with clean room and laboratory best practices. The pump is convection cooled by dual high flow fans, ensuring consistent thermal management and smooth operation even during multiple consecutive test cycles. Encapsulation within the enclosure significantly reduces operational noise, making this system exceptionally well suited for indoor laboratories and controlled test facilities in the cosmetic, medical device, food packaging, and pharmaceutical sectors.

System control is provided by a dedicated vacuum controller purpose built for automated testing workflows. The controller supports intuitive recipe selection, allowing operators to quickly configure and recall predefined test parameters such as target vacuum level, ramp rates, dwell times, and cycle sequences. This reduces setup time, minimizes operator variability, and ensures repeatable, defensible test results across different products and users. The result is a streamlined testing process that enhances productivity while maintaining strict control over critical test conditions.

If you are looking for a portable, professional grade vacuum test solution that combines visibility, automation, and reliability in a single system, this platform is designed to exceed expectations. To explore additional custom systems, applications, and real world implementations, CONTACT US TODAY!

We have many more resources on our website that you should check out

We make Robustly Designed and Quality Engineered Systems. You should check out some of our other items we carry; click on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers