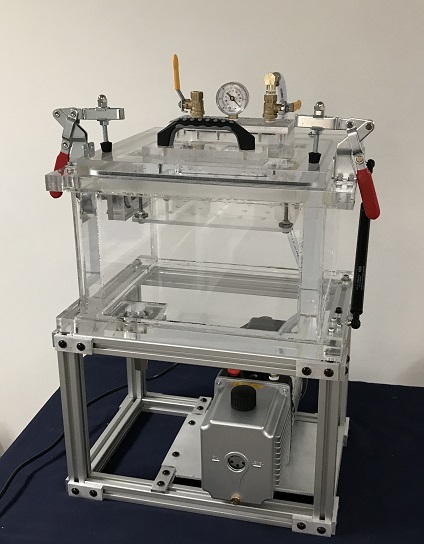

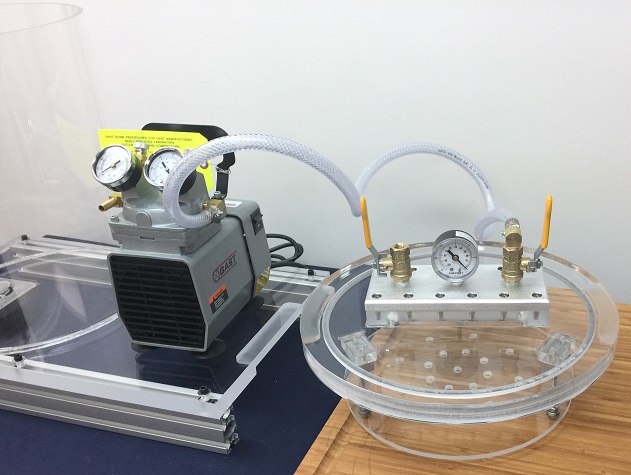

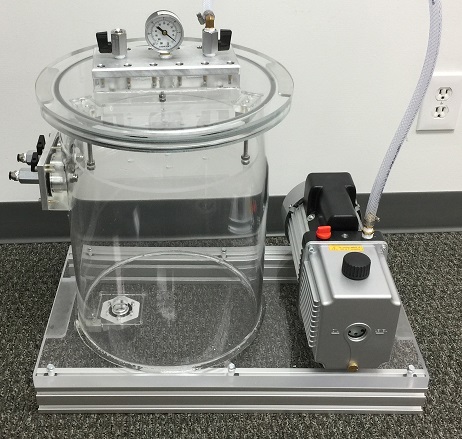

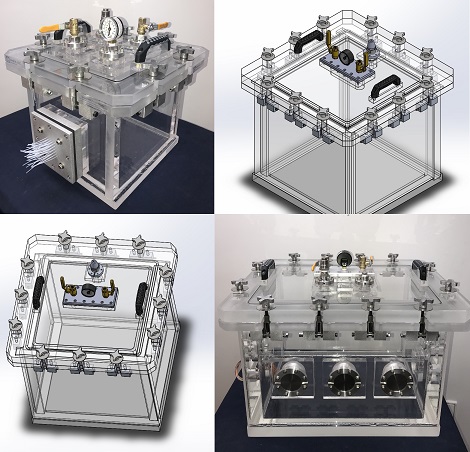

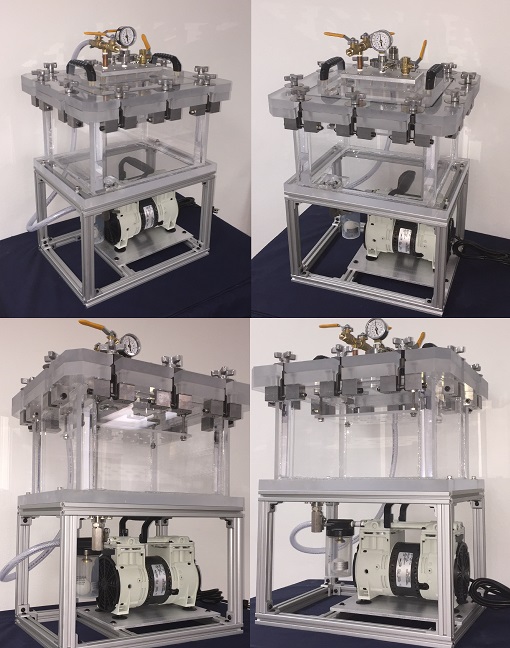

Bubble Emission Testing Chamber System, Clear Acrylic Box, Electrical Pump 12 W x 12 D x 12 H

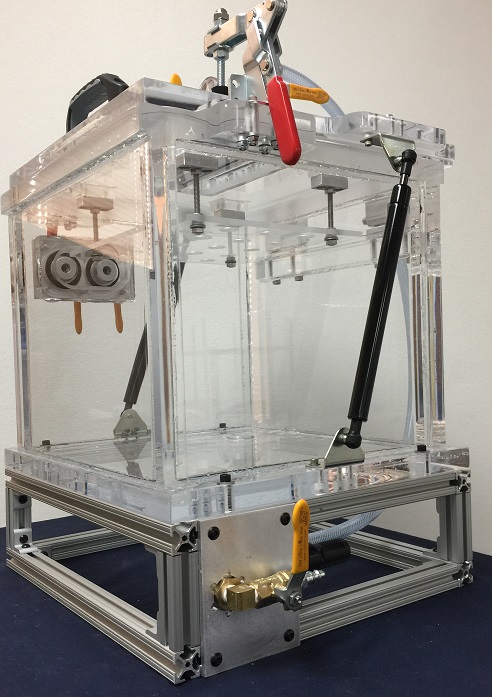

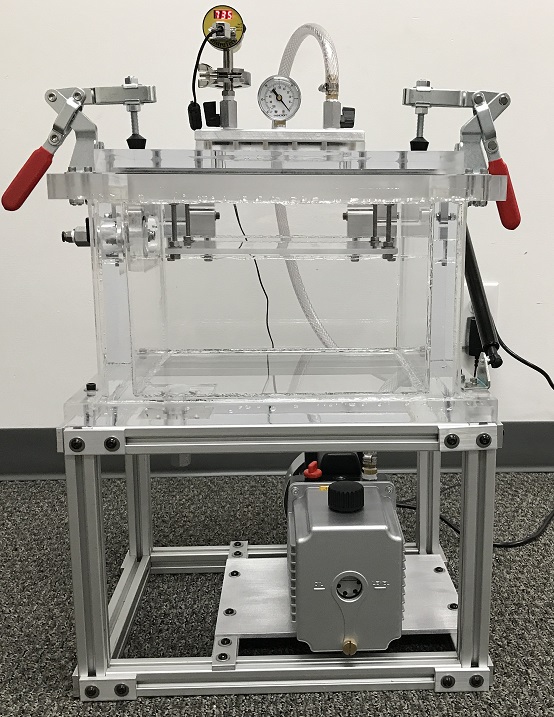

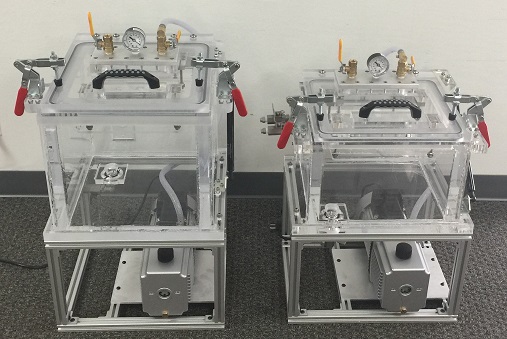

Additional Vacuum Bubble Leak Tester Images

Please take a look at additional product images of our ASTM D3078 Bubble Leak Testing System. All our products can be modified and customized to your requirements. Please contact us if you are looking for a custom Bubble Leak Testing System.

Supporting Resources

to consistently perform and meet your needs!

Supporting Resources for Vacuum Bubble Leak Tester

USER MANUAL: [Document #:808873] - WEB BASED

USER MANUAL: [Document #:808873] - PDF

ARTICLE: Bubble Leak Testing using an Acrylic Vacuum Chamber

Product Specifications

Features

Description

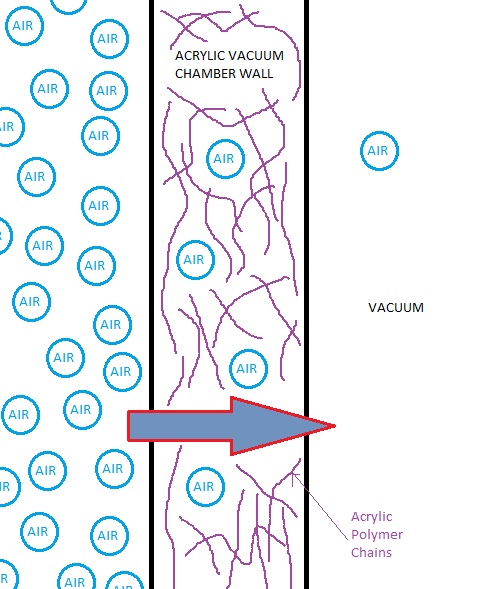

The Bubble Leak Testing System from Sanatron is a precision-engineered solution designed for reliable seal integrity testing. This system is housed in a durable 12-inch cube constructed of high-quality clear acrylic, allowing for easy observation during testing. It utilizes a rotary vane vacuum pump, which ensures accurate and repeatable results when testing a wide variety of seal types. Whether you're working with plastic, metal, or flexible materials, this system will effectively detect even the smallest leaks, making it an invaluable tool for industries where quality and performance are paramount. The ASTM D3078 compliance guarantees that this system meets rigorous industry standards for leak detection and seal integrity, providing you with confidence in the results.

Designed for bench-top use, this compact yet robustly built system is ideal for labs, quality control departments, and production facilities. It allows for precise seal integrity testing with ease, saving you time and money by identifying issues quickly before they become costly problems. The quality manufacturing of the system ensures long-lasting durability and superior performance even in demanding environments. The user-friendly design also makes it easy for operators to quickly set up and get started with minimal training, yet it delivers results that meet the highest industry expectations.

Don't settle for less when it comes to the precision of your seal integrity testing. The Bubble Leak Testing System is the ideal solution to ensure your products meet rigorous standards every time. This is an investment in quality you cannot afford to overlook. We understand that different applications may have unique needs, and we are pleased to offer customizations to meet your specific requirements. Reach out today to discuss how we can tailor this system to fit your needs. Take control of your testing processes with Sanatron expertise and deliverability. Act now and elevate your testing capabilities to the next level!

Sanatron Quality Testing Systems are much better than a Recall or an Unplanned Corrective Action

If you think that you do not have the time or the resources to implement a proper Quality Control Program, then you certainly will not have the time or the resources for unprompted Corrective Actions after Faulty or Leaking Products have reached your Customers.

Imagine having to explain to your team, your superiors, and your customers as to why there are so many quality defects. Imagine having to explain what you could have done to prevent it. Imagine dealing with field alerts, recalls, or having to contend with your auditors as to why you don’t have a Quality Control or Leak Testing Procedure in place.

Fortunately, our Vacuum Bubble Leak Testing Systems will allow you to produce Great Products and will help you to perform the following Test Protocols:

ASTM D3078

Standard Test Method for Determination of Leaks in Flexible Packaging by Bubble Emission

ASTM D4169 Standard Practice for Performance Testing of Shipping Containers and Systems

ASTM D4991

Standard Test Method for Leakage Testing of Empty Rigid Containers by Vacuum Method

ASTM D5094 Standard Test Methods for Gross Leakage of Liquids from Containers with Threaded or Lug-Style Closures

ASTM D6653

Standard Test Methods for Determining the Effects of High Altitude on Packaging Systems by Vacuum Method

ASTM E515 Standard Practice for Leaks Using Bubble Emission Techniques

MIL-STD-810 MIL Standard Immersion Test 810G

MIL-STD-3010C MILITARY STANDARD: TEST PROCEDURES FOR PACKAGING MATERIALS.

FED-STD-101–Test Procedure for Packaging Materials: Method 3028, Method 5009

AIAA 2000-3735 Aerospace Leak Test Requirements Such as the Detecting Gross Leaks

Do things right the first time! Everyone will benefit! Get your Quality Leak Testing System. Contact Us now.

WAIT! Take a look at similar Items you may like…

We make Robustly Designed and Quality Engineered Systems. Check out some of our other items we carry that you can combine/integrate with your systems or projects.

Additional Comments

1. Depiction: We go above and beyond to represent our products the best we can, but all images are for reference only. If you want the exact dimensions of a product, please refer to the product drawing. If the drawing is not present, please contact us.2. Discount: If you are ordering more than one item you will qualify for a discount, contact us for more details. No discount will be given after you have ordered and then realized you can get a discount. We put in a lot of effort writing this and we don`t reward failure to read our descriptions. However, since we are nice guys, we will give you a discount on your next order.

3. Shipping: The shipping rates are for the lower 48 states only; additional shipping charges apply to Alaska, Hawaii, and international orders. Keep in mind that international order will also be subject to duty and other charges.

4. Products: Our products are built-to-order; therefore, your product can be customized, but you must let us know beforehand. The pricing, shipping terms, and lead time apply to orders of less than three (3) items. If you are ordering more than 3 items, you should contact us to discuss your quote.

5. Return Policy: 14 days on all standard products. We stand 100% behind our products. If there was a mistake on our part, you will be refunded 100% of your money including shipping. If the mistake was on your part or you decided that you didn`t want it after all, you will pay for shipping and we will fully refund rest of your money. Chamber must be insured during return shipping for the price that you paid for and in a non-damaged condition. Return Policy does NOT apply to custom items, jobs, or products. If you have asked us to modify any of our standard products, you will not be able to return your item.