What is the ASTM D6653 Protocol?

ASTM D6653 establishes a standardized vacuum-based methodology for evaluating how packaging systems respond to the pressure differentials encountered during high altitude transportation. Under these scenarios, the reduction in ambient pressure can induce expansion forces within packages that may compromise seals, closures, internal cushioning, or the product itself. Rather than producing strictly quantitative pass or fail metrics, the method is intended to provide qualitative insight into whether a given packaging configuration is robust enough to tolerate altitude induced stress without visible deformation, leakage, or functional degradation. By simulating altitude conditions inside a controlled vacuum chamber environment, the test allows manufacturers and engineers to reproduce worst case transport scenarios in a repeatable and standardized manner before products ever enter the distribution chain.

The scope of ASTM D6653 emphasizes packaging system evaluation as an integrated whole, encompassing the product, primary packaging, secondary packaging, and closure mechanisms as they would appear in actual shipment. The standard references several complementary ASTM methods, including bubble emission testing, rigid container vacuum testing, and gross leak detection, acknowledging that altitude simulation often overlaps with leak integrity concerns.

This, in a quick summary, covers most of it it.

What Equipment do I need in order to perform the ASTM D6653 Test?

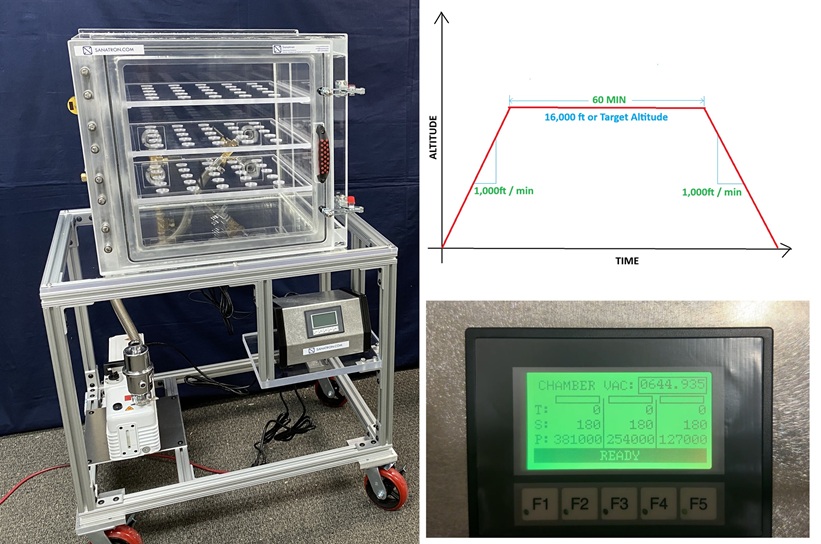

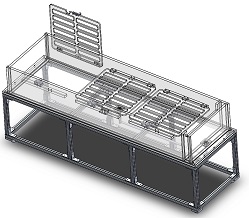

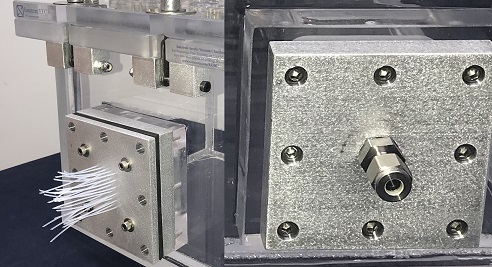

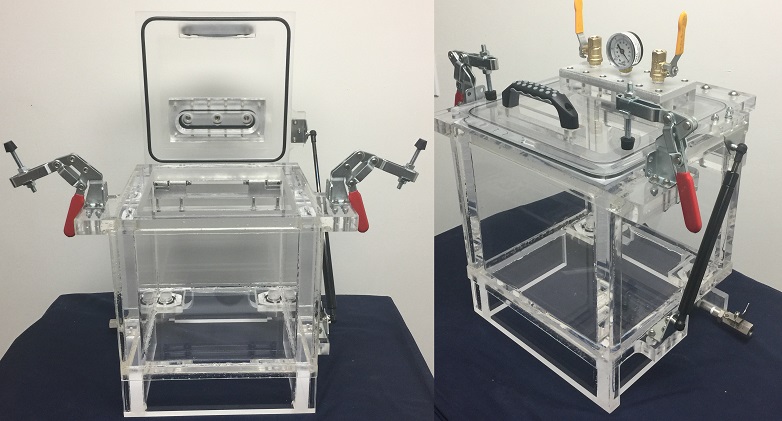

Vacuum Chamber

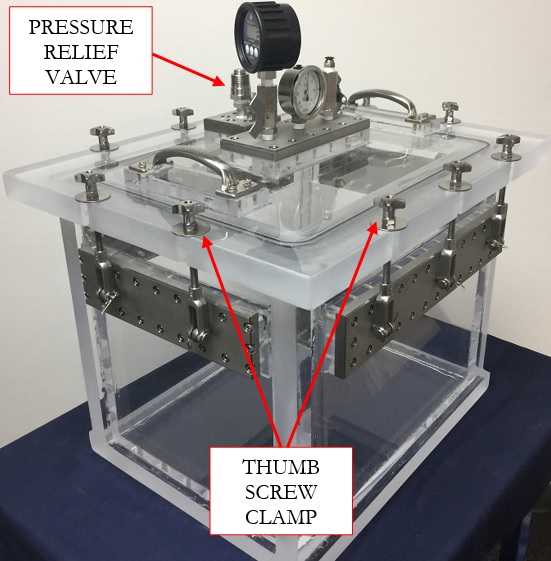

Ideally, you will need a vacuum chamber, preferably acrylic, to allow for full visibility of test specimen during the test run. A stainless-steel chamber may be used if the door is acrylic because it will allow visibility from the front side.

Vacuum Pump

You will need a vacuum pump capable of reaching your target altitudes. A good vacuum pump would be a rotary vane vacuum pump or a piston pump.

Vacuum Controller

The vacuum controller needs to be capable of ascend and descend rates. At minimum needs to be programmable for target altitude and hold time.

Sanatron does offer standard solutions that you can check out here

We have more resources with regards to the vacuum bubble leak test that we invite you to read.

Altitude Test Chamber, How Vacuum Chambers Simulate High AltitudesAltitude Package ASTM D6653 Leak Testing Systems

Altitude Simulation Systems