ASTM D4991 is a widely recognized standard test method for leakage testing of empty rigid containers by vacuum. It is specifically designed to evaluate a container’s seal integrity under reduced pressure conditions, simulating the pressure differentials that occur during air transport In practice, this method helps determine if a container can withstand a pressure drop (typically up to about 95 kPa or 13.8 psi differential) without leaking Ensuring containers meet this criterion is critical for industries that ship liquids by air, especially hazardous materials, as even a small leak can lead to contamination, safety hazards, or regulatory non-compliance. ASTM D4991 provides a non-destructive means of testing packaging integrity – containers that pass the test remain intact and can continue to be used, unlike destructive burst tests. By using vacuum-induced pressure differences, the standard pinpoints the onset of leakage in a controlled setting, offering confidence that products will remain secure and uncontaminated during transit.

Elevate your leak detection program with ASTM D4991—the gold standard for precision and reliability in bubble leak testing. A thorough understanding of this industry-leading protocol is crucial for achieving accurate results and upholding the highest quality benchmarks. Don’t leave compliance to chance. Secure the official documentation today to safeguard the integrity of your testing procedures with complete confidence.

Shortcomings of this Testing Method

Ethylene Glycol will make the water bath more viscous. This means that the sensitivity of the bubble leak test will be decreased as the viscosity of the immersion fluid increases. This is why we recommend to use plain water as the immersion fluid as opposed to Ethylene Glycol solution. Not only will this simplify the testing procedure, it will also increase testing sensitivity.

Another shortcoming is that at 13.9 psi of vacuum, the immersion fluid will begin to degas and boil and a large number of bubbles will be created which will decrease the signal to noise ratio and interfere with the testing results. While the higher vacuum will ensure that the water intrusion into the test specimen is maximized, hence easier detection of liquid inside the container during test, the higher vacuum will also interfere with visual bubble detection.

Conclusion

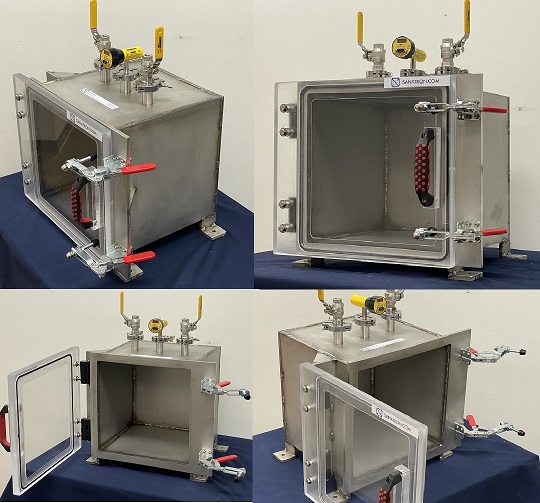

ASTM D4991 has established itself as a crucial standard in the intersection of packaging engineering and transportation safety. By detailing a clear vacuum leak test procedure for rigid containers, it provides manufacturers, engineers, and regulatory professionals with a reliable tool to assess container performance under simulated flight conditions. The testing process, from submerging samples in a fluid-filled vacuum chamber to observing for bubble trails, is rooted in sound engineering principles that reveal weaknesses in seals or materials before they can cause problems down the line. Industry adoption of ASTM D4991 spans pharmaceuticals, chemicals, food, and beyond, reflecting the universal need for leak-proof packaging in any sector that ships liquids. Its alignment with regulatory requirements (such as the UN and ICAO 95 kPa pressure differential rule) further underscores its importance: products that pass ASTM D4991 give confidence of compliance and safety in transit

In comparing ASTM D4991 with other standards and methods, we see that it fills a specific role focused on vacuum-induced leak detection for rigid containers, complementing other tests for flexible packs, altitude effects, or high-precision leak detection. The standard’s straightforward yet effective approach, using visual detection of leaks, makes it both technically robust and practical for routine use. Packaging engineers value the fact that it is generally non-destructive and can be integrated into iterative design testing and quality control without destroying every sample. Meanwhile, regulatory officials and safety auditors appreciate that ASTM D4991 provides an evidence-based assurance that packaging will hold up under the stresses of air transport, thereby protecting people and the environment from accidental leaks.

In summary, ASTM D4991 combines technical rigor with real-world relevance. It exemplifies how a well-crafted testing standard can improve industry practices: fostering safer shipments, guiding compliance with international regulations, and ultimately ensuring that whether it’s a vial of medicine or a drum of chemicals, the contents stay securely contained throughout their journey. The confidence gained by adhering to ASTM D4991 resonates through supply chains. From engineers who design packaging, to authorities who enforce transport laws, and to end-users who trust that the products they receive are safe and intact. Using this standard, companies not only meet required specifications but often exceed them, bolstering overall quality assurance for packaged liquids in air transit. The result is a higher level of safety and reliability that benefits everyone involved, achieved through the meticulous process and principles defined in ASTM D4991.

Strengthen your packaging integrity and protect your products with ASTM D4991 compliant testing solutions. CONTACT US today to learn how we can help you ensure the highest standards of safety and quality!

We have more resources with regards to the vacuum bubble leak test that we invite you to read.

Vacuum Bubble Leak Test, A Comprehensive GuideBubble Leak Testing using an acrylic vacuum chamber

See our Vacuum Bubble Emission ASTM 3078 Leak Testing Systems