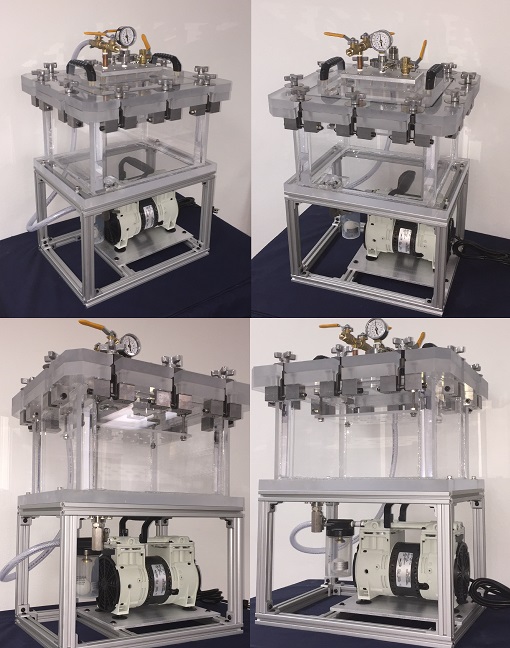

Custom Made Vacuum Cable Feedthroughs installed on a Square Vacuum Chamber

Not only can we install any off-the-shelf vacuum feedthrough available onto a vacuum chamber, we can also make our own custom vacuum feedthroughs and specifically install them in a way that will work best for you. An aerospace client looking to test various custom cables inside a fully transparent vacuum chamber reached out to us to see if this is something that we can do.

Of course, this something that we can do, working with high tech vacuum instruments and vacuum equipment is what we do day in and day out. We have been in business since 2008 and this is all we have done during this time. We have worked with all branches of the us government, all fortune 500 companies, all Russel 2000 companies. The other day we estimated that we have our hand in 80% of all products you come across on your daily basis. When you operate your appliances in the morning, we have worked on that. When you get into your car to drive to the store, we have worked with all major car companies. When you pick out any food item at the store, we have worked with almost all food and beverage packager. When you stop to fill up you car on your way home, we have worked with every energy company you can imagine. So why would you think a custom cable feedthrough installed onto a vacuum chamber would be something that would trouble us? It won’t.

What we came up with is a full transparent vacuum chamber with dimensions of 24 inch Wide, 18 inch Deep, and 18 inch High. We then custom precision machined a vacuum plate to connect to a set of Custom Compact Plastic Submersible Cord Grips. We did this by designing an O-ring groove and included an specifically fit O-ring to prevent air leakage. We then installed the Cord Grip which are designed to fit in small or tight areas. Rated at IP68 and 69K which enables protection from high pressure and continuous submersion in water. Furthermore, these cord grips are rated NEMA 4X, 6, and 12 for corrosion protection, water jets, oils and lubricants. When the cable is fed through, a rubber bushing will create an air tight seal between the cable and Cord Grip when the outer nut is tightened. This will enable our customer to test the cable in full vacuum without leakage and compromising of vacuum performance. The chamber also comes with two (2) x 1/4 inch NPT Brass Valves and a dial vacuum gauge which indicates the vacuum level via a dial on a dual scale in inHg or kPa. The O-Ring is situated inside a precision routed Dovetail O-Ring Groove on the lid which also has two lid handles enabling easy lifting of the fully removable vacuum lid. If you are looking to make a custom vacuum feedthrough, contact us, we are happy to hear about your projects.

Similar Items

Our clients prefer to work with us because we are Experts in Vacuum Science and Technology. What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers