Opaque Vacuum Chamber

An acrylic vacuum chamber does not always need to be transparent, there are instances when a vacuum chamber needs to be made from acrylic and that acrylic also needs to be fully opaque where no light can pass through.

A customer of ours reached out to us to see if it was possible to design and built a vacuum chamber that is made from polymers but is also opaque. They were testing some light sensitive equipment where it was critical that the amount of light coming in and going out was strictly controlled for. When they reached out to us, we knew that opaque acrylic existed, but we only knew about thinner acrylic panels, those which were about 0.25 inch thick. Acrylic this thin cannot be used for vacuum applications because the forces applied to the wall at 15 psi are large and will risk beveling, bending, and damaging the walls at full vacuum. Imagine a vacuum chamber which that is 10-inch by 10-inch and at 15 psi of vacuum, the force applied to the wall due to pressure differential equals the area times the pressure which is 1500 lbs. That is the weight of a car being applied to a 0.25-inch-thick acrylic panel, barely enough. So we reached out to our supplier to see if they had something thicker, and they did.

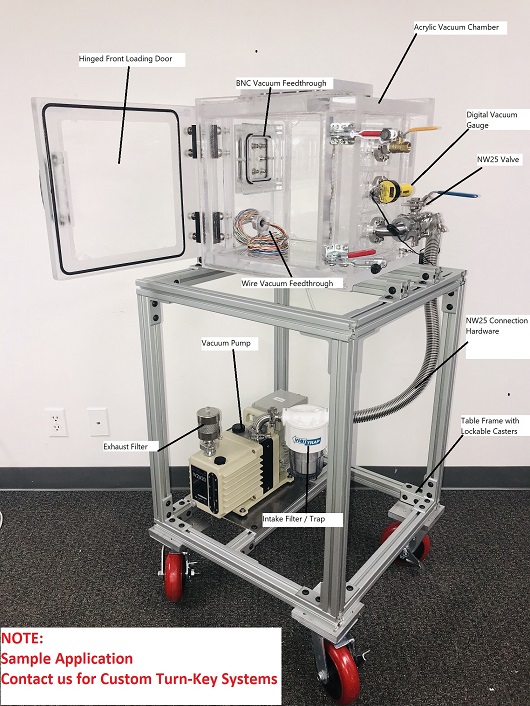

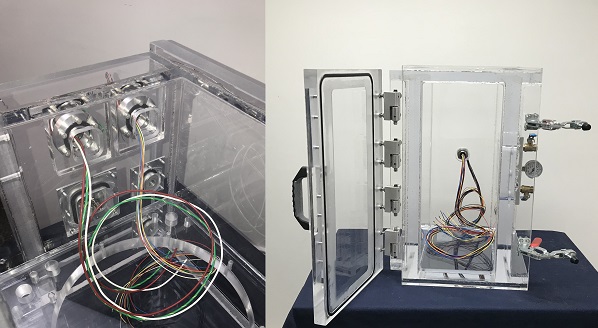

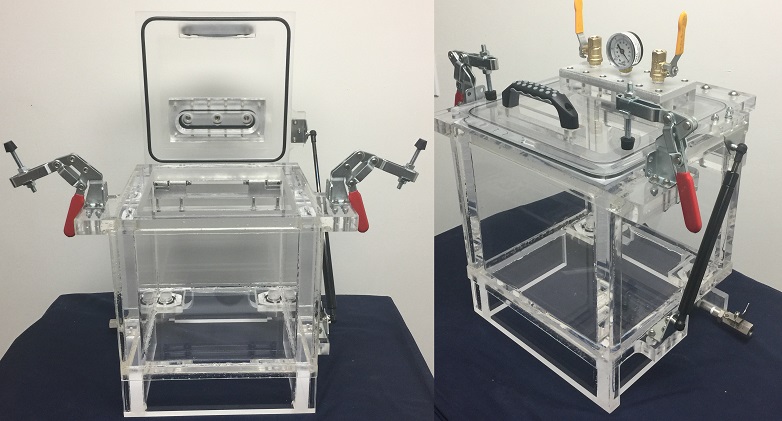

What you are looking at is an opaque acrylic vacuum chamber that is 10 inch Wide, 10 inch High, by 20 inch Deep. This is a hinged door, front loading chamber where the door fully swings open towards the front right allowing for easy chamber loading. The door comes with two hinges, two clamps, and one lid handle. Another customization made to this chamber is a 15 pin D-SUB (subminiature D) Connector on the Left Wall at center. This chamber can be easily placed onto a table top and operated as a bench top unit. Looking for a vacuum chamber? Let us know how we can help you. Contact us.

Some of our Popular Items

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). Check out some of our other items we carry that you can combine/integrate with your systems or projects.

Complete List of Articles Related to Acrylic Vacuum Chambers