Vibration Table Installable Vacuum Chamber

The ASTM D3580 as well as the ASTM D4728 use a vibration testing method to quality test packages and shipping containers that will be subjected to vibration due to transport. But what happens if you have several ASTM testing protocols to complete and would like to find a way to consolidate your testing methods so that you can do two or more ASTM testing protocols at once in order to save time, money, and resources; is this something that can be done?

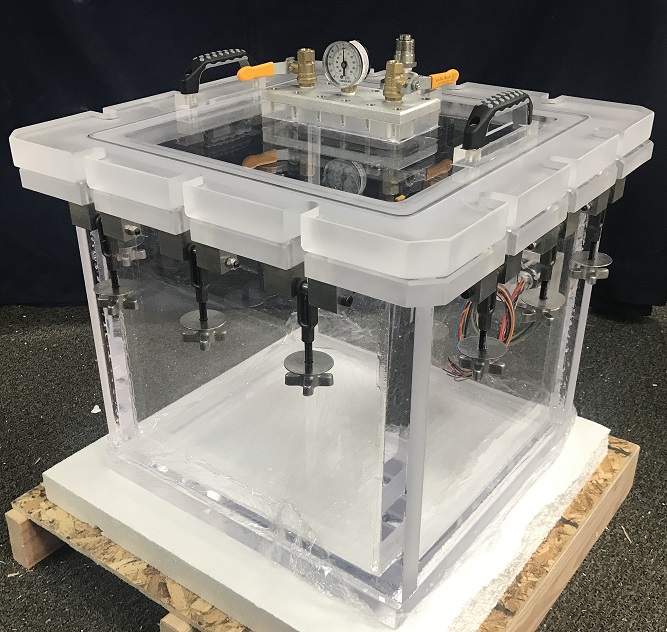

Of course it is. Our customer combined the ASTM D3580 or the ASTM D4728 Testing Method with the ASTM D6653 Altitude Testing Method. This was done by placing a vacuum chamber onto a vibration table. As the Vibration table is running it’s protocol, the Vacuum Pump and Controller are running the ASTM D6653. This means that two package testing methods are done simultaneously.

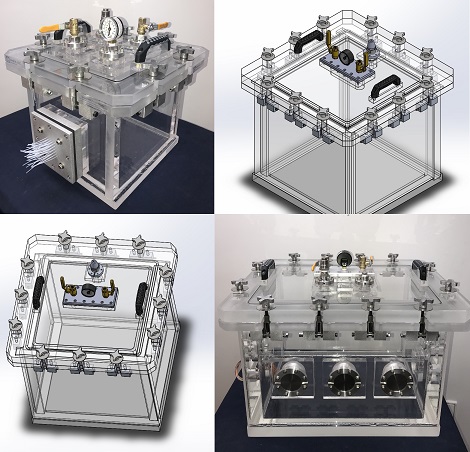

You are looking at a front loading vacuum chamber made from acrylic. The internal dimensions are 18 inch Wide, 18 inch Deep, and 22 inch High. The vacuum chamber also has Through holes on the bottom of wall outside lip. This will allow for the vacuum chamber to be connected to the vibration table by running four bolts and tightening them fitting the chamber into place. The vacuum chamber also has two door clamps, one lid handle, and four hinges. There is also a 2 inch diameter hole on the top center wall allowing for vacuum components to be connected to it. If you are looking for a vacuum chamber that is intended to be used for a specific custom application, contact us to see how we can help make that happen.

We have many more resources on our website that you should check out

We are an Engineering Excellence Company. What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers