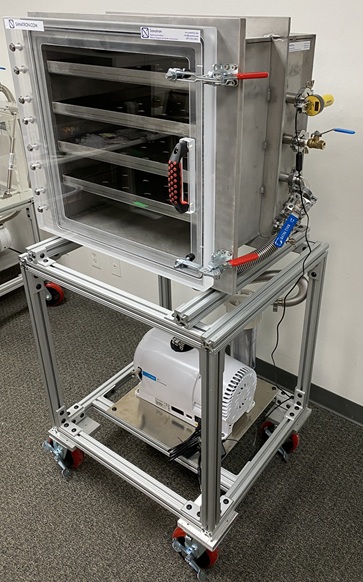

Turnkey Portable Stainless Steel Vacuum Chamber with Dry Scroll Pump

The Sanatron Portable Stainless Steel Vacuum Chamber with Dry Scroll Pump is robustly designed and quality built for laboratories and production environments where performance, durability, and portability are a absolute must. Designed as a front-loading 20-inch cube, this vacuum system features a front loading, fully transparent, Acrylic Door that provides clear visibility of internal processes while maintaining an almost perfect vacuum seal. Equipped with removable stainless steel perforated shelves that ensure uniform airflow, making it ideal for controlled vacuum drying, degassing, and conditioning operations. The table cart which is constructed with a robust 8020 aluminum frame, the entire system rests on lockable swivel casters for effortless mobility, transforming it into a truly portable vacuum platform that can be positioned anywhere in your lab or cleanroom with minimal effort.

This complete turnkey vacuum system integrates a high-performance dry scroll pump paired with a Visitrap inline filter and a NW25 Vacuum valve assembly, ensuring oil-free, contamination-free operation suitable for biotech research, pharmaceutical manufacturing, and advanced medical technology applications. This Particular Dry Scroll Vacuum Pump (Supplied by Agilent) delivers high pumping efficiency without introducing hydrocarbons, making it an environmentally responsible and maintenance-friendly choice. Every component, from the welded stainless chamber to the ergonomic layout, reflects our dedication to quality and functionality. Built to perform under demanding schedules, this vacuum system represents the harmony of clean design, quiet operation, and scientific reliability, suitable for research institutions and production engineers who demand more than just function—they demand dependability.

If you are looking for a turn-key vacuum system with the reliability and craftsmanship trusted across the biotech and pharmaceutical industries, contact Sanatron today. Our engineering team can customize this system to your precise specifications. Whether that means adjusting dimensions, adding sensors, integrating automation controls, adding vacuum feedthroughs, or other complex customizations. Contact us today!

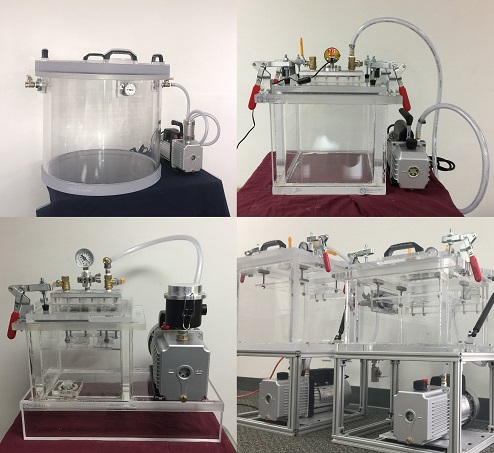

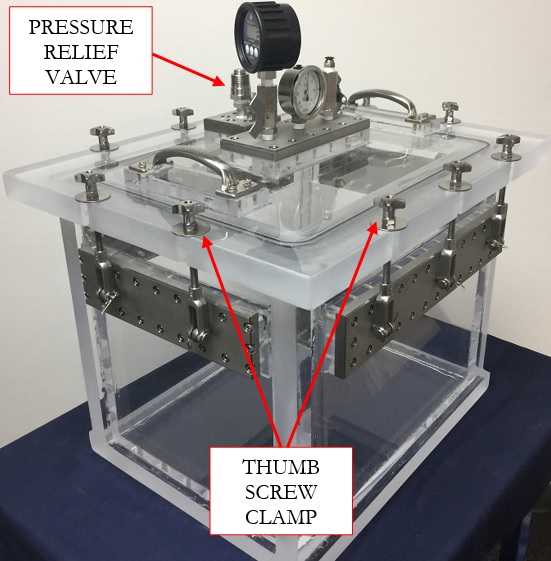

WAIT! Take a look at similar Items you may like…

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers