Laser Beam Welding Low Vacuum Purge Chamber

This was actually not a vacuum chamber per se but more like a vacuum purge unit. Our customer, who is from academia. had gotten a custom made CNC laser beam welding unit. They were looking for a way to purge the surrounding air and fill it with inert gas in order to prevent oxidation and contamination from the laser heat source. We suggested several small chambers with a viewport for their laser welder. However, they wanted to encase the whole CNC unit inside a chamber which would be lift able by a crane for easy access.

After going back and forth with us trying to talk them out of getting such a large chamber and encasing the whole unit, we finally agreed because they were only looking to purge the air out and inject argon; hence this unit would never go below a gauge vacuum of - 3psi.

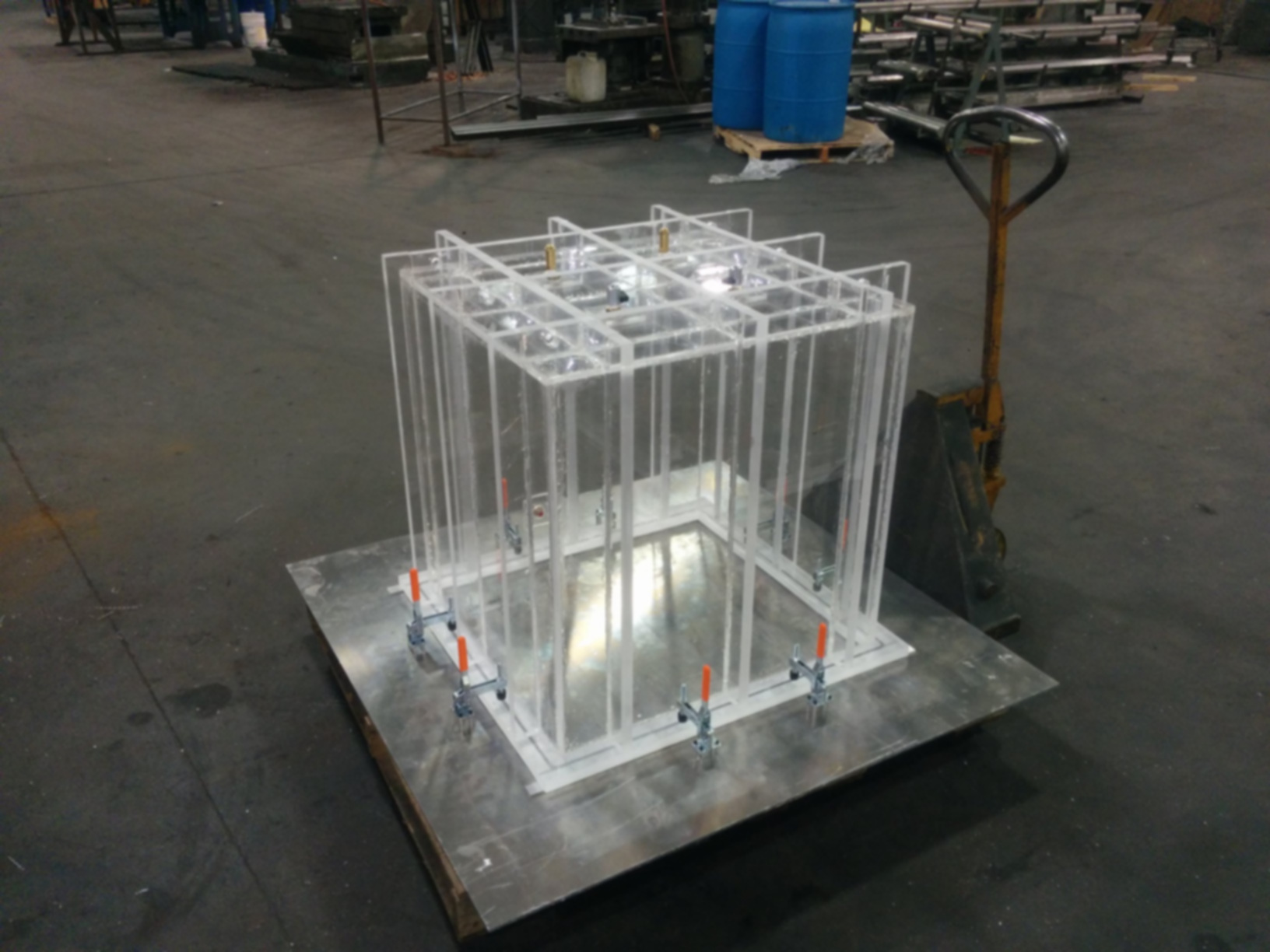

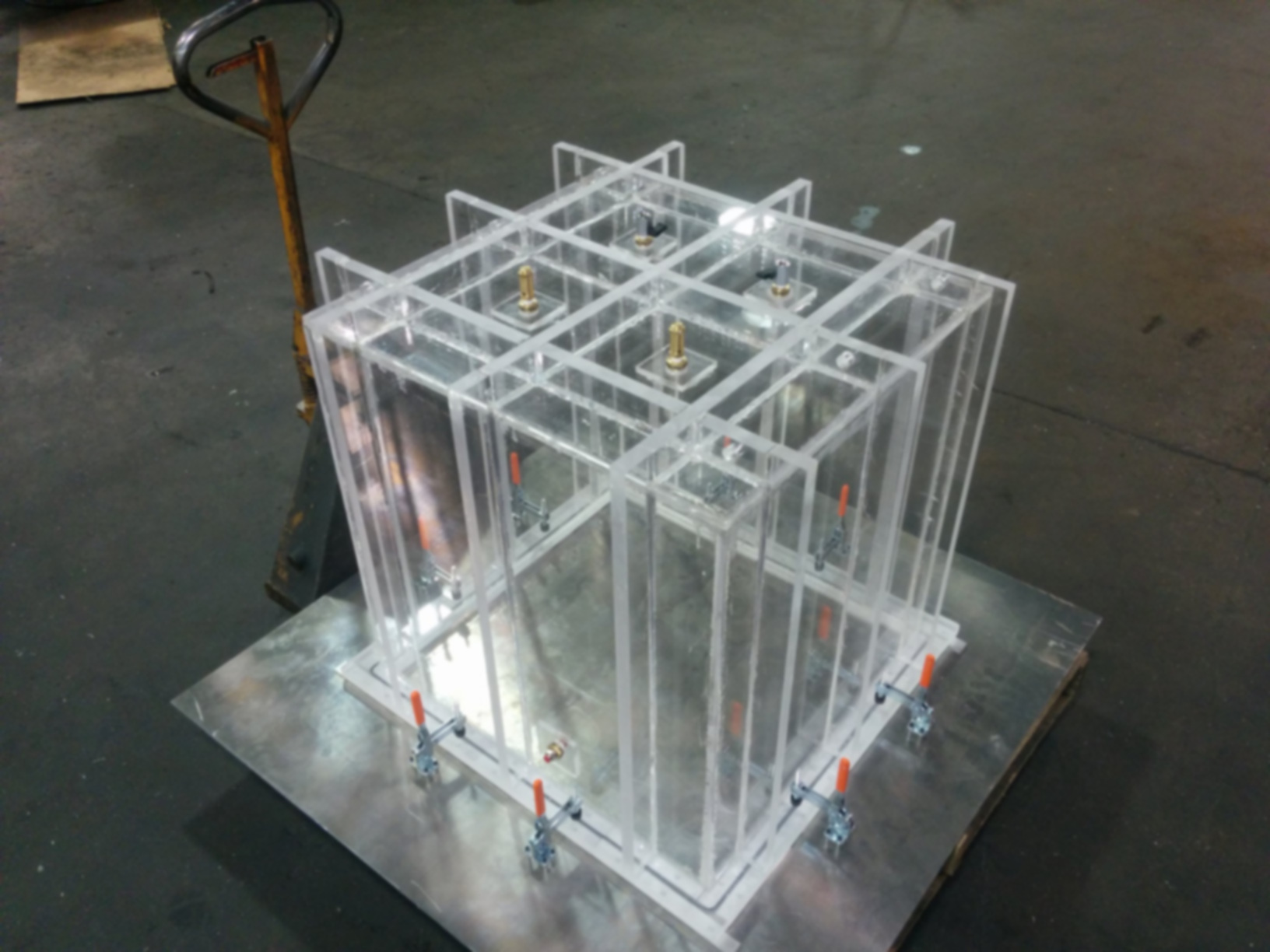

What you see here is a vacuum purge chamber for a CNC laser welder with dimensions of 28 inch wide, 30 inch deep, and 35 inch high. The whole chamber sits on an aluminum plate that has clamps in order to clamp down the chamber during the purging process. We also added a lifting holes and reinforcement ribs for structural robustness in case one of their graduate students forgets to turn off the vacuum pump...

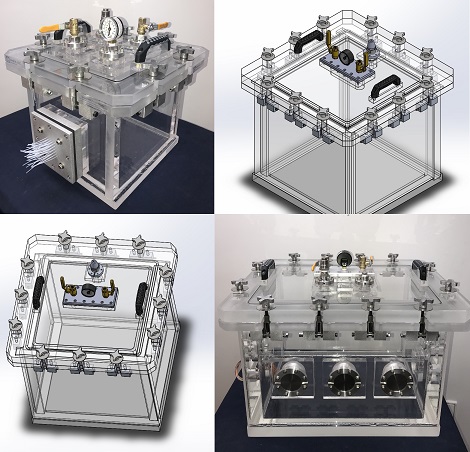

Similar Items

Our clients prefer to work with us because we are Experts in Custom Fabrication (especially Polymer Fabrication). You should check out some of our other items we carry; click on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers