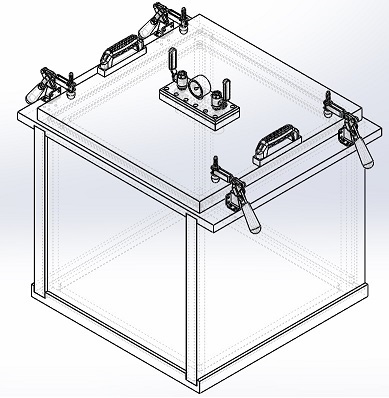

Acrylic Vacuum Chamber, Cube, 14 inch inside dimensions, Top Load Model, Clamping Lid

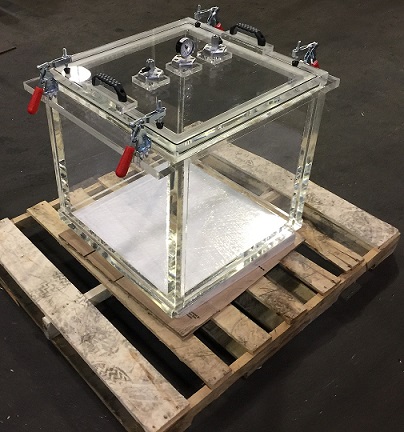

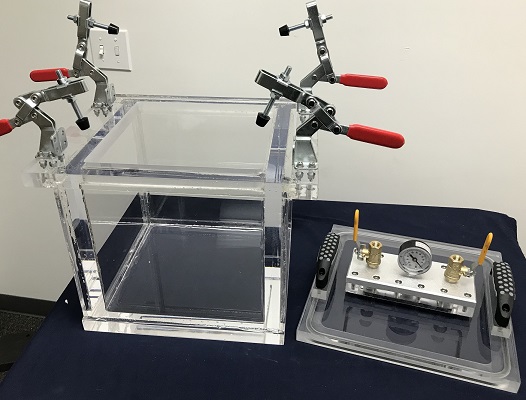

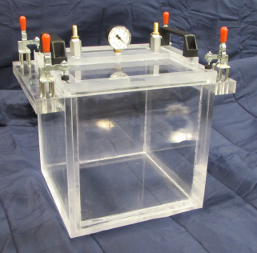

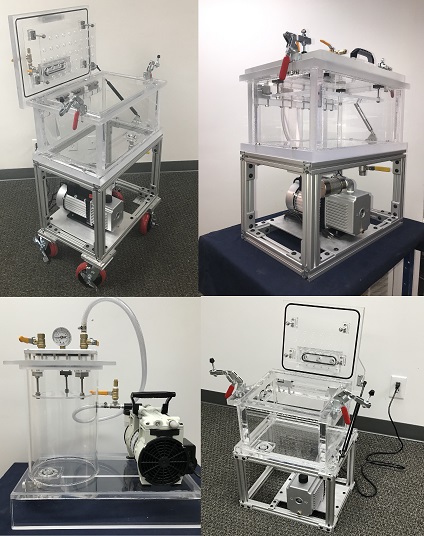

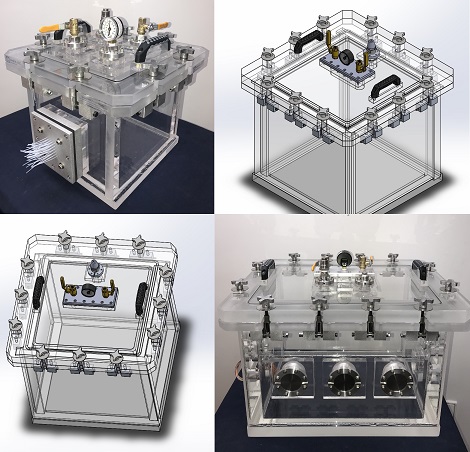

Additional Vacuum Chamber Images

Please take a look at additional product images of our Top Load Acrylic Vacuum Chamber with Removable Lid. All our chambers can be customized. Please contact us if you are looking for a custom vacuum chamber.

Supporting Resources

ARTICLE: Clear Acrylic Vac Chamber ReviewARTICLE: Selecting a Proper Vacuum Pump for your Acrylic Vacuum Chamber

ARTICLE: Customizing your Acrylic Vacuum Chamber

Product Specifications

Features

Description

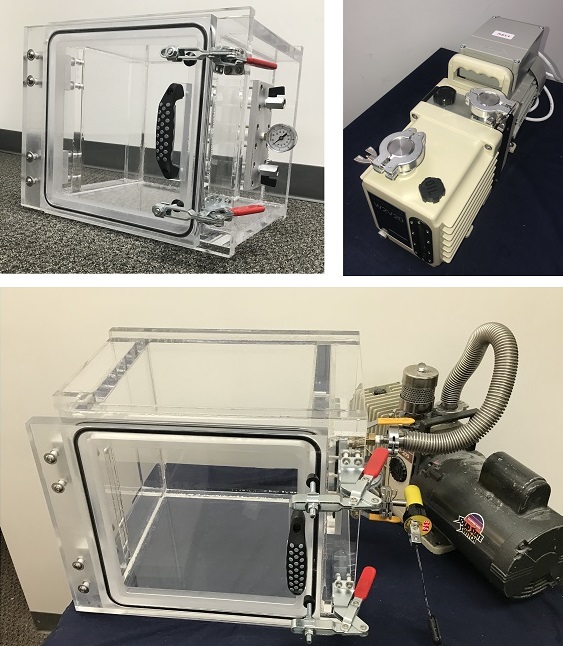

14 inch X 14 inch X 14 inch inside dimensions chamber is made of clear acrylic which is fully transparent enabling a full view of chamber interior during operation. This is a complete clear acrylic vacuum chamber; assembled and ready for use. It comes with a vacuum gauge, two valves, two handles, and four clamps. The vacuum gauge, valves, and clamps are on the lid, but can be moved if requested.

A Vacuum chamber can also be used as a Desiccator cabinet. Common applications include vacuum testing, vacuum product testing, degassing, defoaming, mixing liquids, bubble leak testing, vacuum sealing, vacuum drying, vacuum encapsulation, vacuum joining, vacuum impregnation, atmospheric testing and simulation, biological tests or storing samples under sustained low and intermediate vacuums.

Please note that plastic material is permeable; therefore, acrylic chambers as such may not maintain a stable vacuum level over extended period of time. For stable vacuum levels in this chamber, it is advisable to either leave the vacuum line or pump constantly connected to this chamber or add a vacuum controller to control vacuum levels.

One of the most common mistakes people make is to try to source every single part for their vacuum system themselves. The end results is either the wrong vacuum pump, the wrong connection hardware, or a sub optimal Vacuum System.

We have sourced the most appropriate vacuum pump for you so that you don’t have to. Get your vacuum chamber and vacuum pump and connection hardware for a complete vacuum system! Click here to get your Vacuum Pump and Vacuum Chamber System

Related Products

Common Applications

■ Quality Control ■ Package Integrity Testing ■ Bubble Leak Testing ■ Altitude Simulation ■ Hi-Pot Discharge Testing ■ Electronic Equipment Testing ■ Vacuum Encapsulation ■ Vacuum Force Decay Testing ■ Regulatory Compliance ■ Degassing Applications ■ Freezedrying / Lyophilization ■ Aerospace Applications ■ Various Manufacturing and Packaging ■ Genetic Engineering ■ Laboratory and Research ■ Automotive Parts Manufacturing ■ Academic Research ■ Scientific Experiments ■ Industrial Applications ■

Check Out Our Work for more ideas

Product Quality Assurance

At Sanatron, quality isn't just a word, it's our promise and our commitment. Our Acrylic Vacuum Chambers come with a comprehensive 5-year warranty, reflecting our confidence and dedication to excellence. Each chamber is robustly engineered for consistent, long-term use, representing the culmination of extensive research, thoughtful design, and continuous improvement.

Our acrylic vacuum chambers feature rugged walls constructed with our proprietary acrylic interlocking technology and specially formulated vacuum-grade adhesive epoxy. Our advanced adhesion methods are among our valuable trade secrets, ensuring unparalleled durability. Thanks to meticulous engineering, common industry issues such as deflection, beveling, collapse, or wall separation are completely eliminated in our chambers.

We offer two convenient options for porting into our acrylic vacuum chambers:

3-Port Plate:

Our proprietary design includes three 0.25-inch NPTF ports. This plate is interchangeable and can easily be upgraded to accommodate vacuum bulkhead ports up to NW25/KF25/QF25 sizes.

Standalone Ports:

Alternatively, chambers can be fitted directly with three standalone NW25 bulkhead ports. Additionally, our standard products seamlessly integrate with KF25/NW25 vacuum connections, offering you exceptional flexibility.

Sanatron chambers achieve an impressive medium vacuum specification of 0.075 Torr (75 microns). They exhibit exceptional leak-tight performance, with an initial vacuum loss rate of just 50 microns per minute, which rapidly decreases and stabilizes. As a result, your chamber will experience a maximum vacuum loss of only 5.25 Torr (0.2 inHg) over a 24-hour period.

We extend our heartfelt gratitude to our many satisfied customers whose valuable cooperation and constructive feedback have continually guided us in enhancing our chambers. Their insights have not only helped us refine our existing products but have significantly elevated the quality and performance for future customers.

Thank you for choosing and trusting us with your vacuum chamber needs!

Frequently Asked Questions

1. What type of vacuum pump is recommended for use with this chamber?

Any rotary vane vacuum pump, whether single-stage or two-stage, will work effectively. A higher CFM pump will help reach your target vacuum faster. Since our chambers have a vacuum rating of 0.075 Torr (75 microns), any vacuum pump rated at 0.075 Torr or lower is suitable. For more detailed guidance on choosing the perfect vacuum pump, please refer to our comprehensive guide: Selecting a Proper Vacuum Pump for your Acrylic Vacuum Chamber.

2. What is the maximum vacuum achievable with this chamber?

The achievable vacuum level depends on your vacuum pump. While our chambers are rated at 0.075 Torr (75 microns), we generally recommend stainless steel chambers for high-vacuum applications due to acrylic’s higher outgassing properties. However, we have reports from customers successfully using turbo pumps to reach as low as 10^(-5) Torr (10 microTorr), though this is not officially verified. At our facility, using an industrial-grade rotary vane vacuum pump, we typically achieve around 0.010 Torr.

3. Do I need additional equipment to operate this chamber?

Yes, you'll typically need a vacuum hose (preferably reinforced vinyl), a 1/4-inch NPT male-to-barb fitting, and a couple of hose clamps, all easily available at your local hardware store. The vacuum valve port on the chamber is sized at 1/4-inch NPT. If you’re uncertain or would prefer expert assistance, please contact us directly—we’re happy to provide suitable connection hardware for you.

4. Will materials expand during the degassing process?

Yes, materials typically expand when subjected to vacuum conditions. We recommend conducting initial experiments with small quantities to determine the optimal volume for your application.

5. Can I safely heat this chamber during use?

Yes, heating the chamber is common practice among many of our customers. The chamber can safely withstand temperatures up to 110°F (43°C). Exceeding this temperature is at your own risk.

6. What makes your chambers higher quality and more affordable compared to competitors?

Sanatron advantage is vertical integration. We purchase materials directly from manufacturers, custom-build each acrylic chamber in-house, and sell directly through our website, bypassing intermediaries. This significantly reduces costs, allowing us to pass the savings on to you. Additionally, since 2008, our extensive expertise in manufacturing vacuum chambers and leak-testing systems has enabled us to perfect every aspect of our process such as material selection and quality control to specialized epoxy formulations and precision welding techniques. When you purchase our products, you benefit from our commitment to exceptional quality, extensive industry experience, and dedicated customer service.

Additional Comments

1. Product Images:

We strive to accurately represent our products with the highest quality images possible. However, please note that all images provided are for reference only. For precise dimensions, please consult the official product drawing. If the drawing is unavailable, feel free to contact us for assistance.

2. Discounts:

We are confident that our products offer exceptional value considering their quality, durability, pricing, warranty, and timely delivery. Discounts are evaluated and provided on a project-specific basis. For inquiries about potential discounts, please contact our sales team directly.

3. Shipping Information:

Quoted shipping rates apply exclusively to the lower 48 states. Additional shipping fees will apply for deliveries to Alaska, Hawaii, and international destinations. International orders may also be subject to customs duties, taxes, or additional fees.

4. Product Availability and Customization:

While we maintain a selection of in-stock products, these items frequently sell out quickly. As a result, most of our products are built-to-order, allowing for customized specifications to suit your specific needs. Please discuss with us of any customizations required prior to placing your order.

5. Return Policy:

We offer a 150-day return period on all standard products, reflecting our unwavering commitment to customer satisfaction. If an error occurs on our end, you will receive a full refund, including shipping costs. Returned chambers must be insured for their original purchase price and returned undamaged. Please note that our return policy does not apply to customized products or special orders. If you have requested modifications to a standard product, it will be ineligible for return.